Safe and stable operations

Basic concept

The Tosoh Group is promoting activities pertinent to safe and stable operations, through its RC promotion system based on the Action Plan for Industrial Safety, a set of guidelines established by the Japan Petrochemical Industry Association in July 2013.

We recognize that ensuring stable operations and employees’ health and safety are management issues of the highest importance. Underpinned by our basic philosophy of environment, health, and safety, and our action guidelines stating that “safety takes precedence over everything else,” we will continue to develop a range of measures for strengthening our safety infrastructure, while fostering a safety-first culture in the aim of zero accidents and zero lost work time though injury. Moreover, we will promote initiatives for business continuity plans (BCP) in preparation for natural disasters and other business risks.

Action Plan for Industrial Safety

List of RC Activity Targets and Achievements: Safety Disaster Prevention and Occupational Safety and Health

Fiscal 2023 results

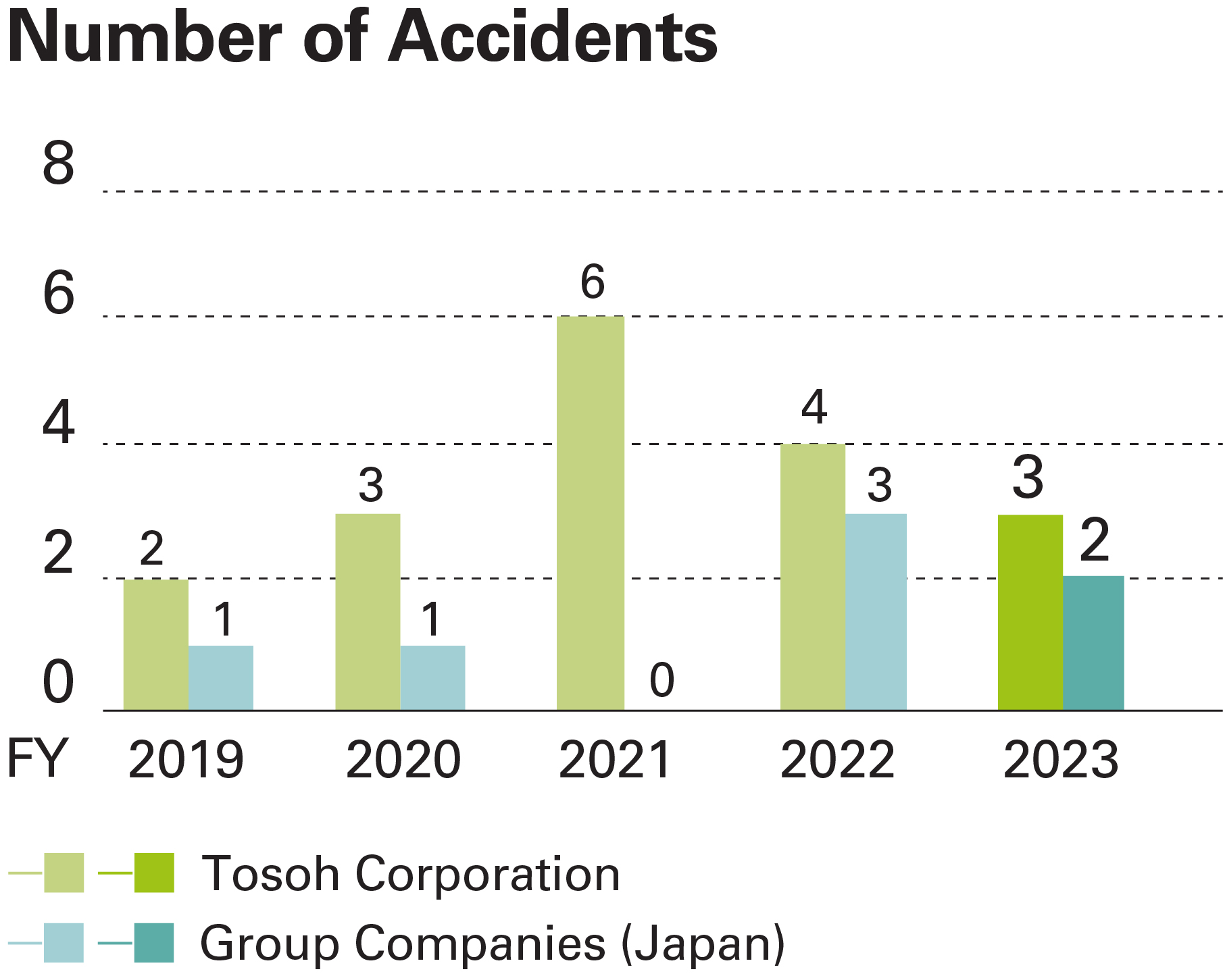

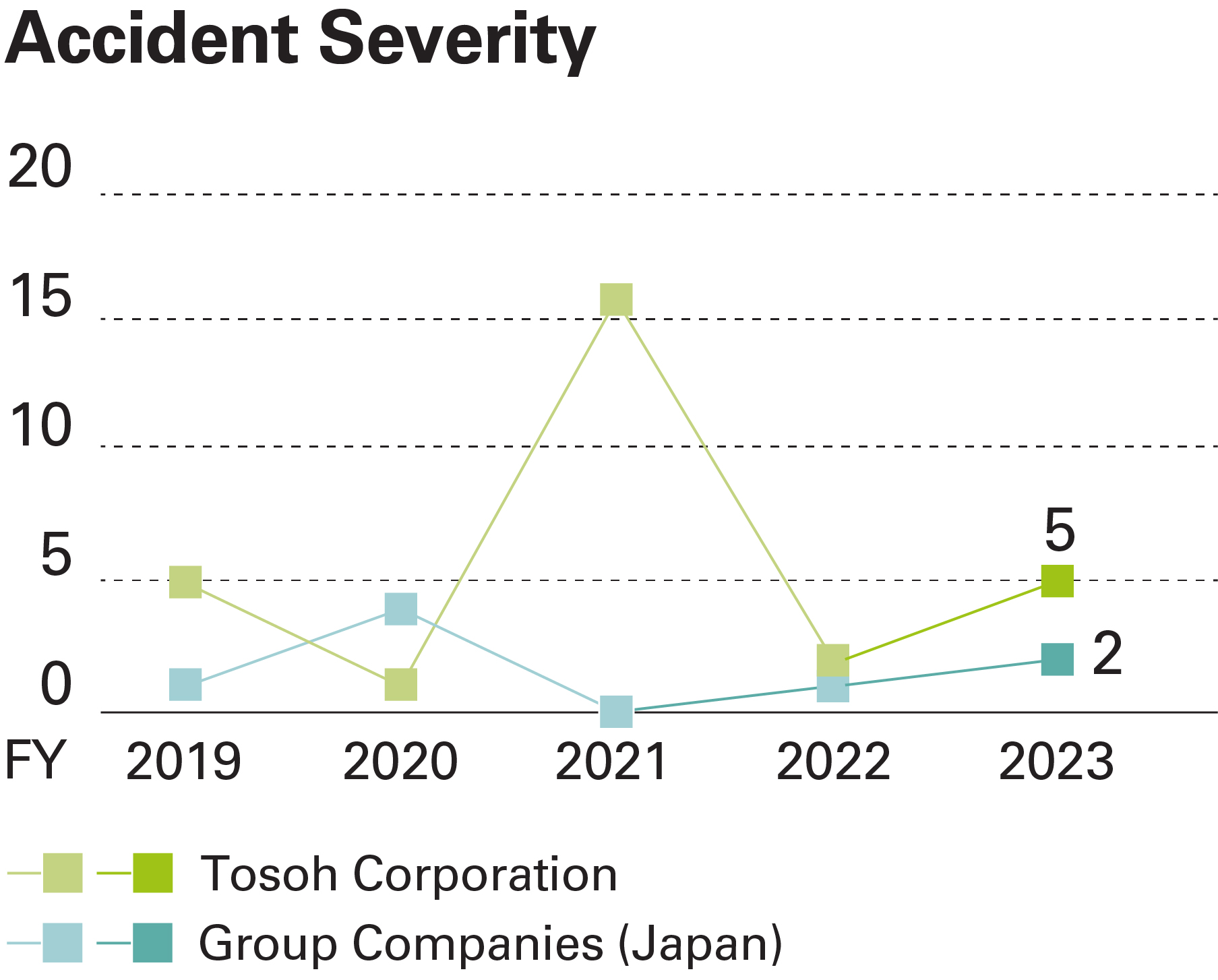

Three accidents occurred at Tosoh facilities in fiscal 2023. In the event of an accident, the Accident Countermeasures Committee investigates the cause and determines countermeasures, and holds a briefing session for the company and group companies to horizontally disseminate information on the incident, with the aim of preventing recurrence.

Fostering a culture of safety

President’s control room visits

Every year since fiscal 2013, Tosoh’s president has visited manufacturing facilities at the Nanyo and Yokkaichi Complexes to hold direct dialogues with staff. This is an opportunity to share management ideas on safety and other on-site issues, which serves to enhance employee motivation. The president visited a total of 281 control rooms and offices over the 11-year period from 2012–2022, interacting with over 6,200 employees. Tosoh will continue its efforts to promote a culture of safety.

Visit to Nanyo Complex

Visit to Yokkaichi Complex

Accident remembrance

As a valuable reminder of the November 2011 explosion and fire at our No. 2 Vinyl Chloride Monomer Plant at the Nanyo Complex, we have erected the safety pledge monument there and also exhibit documents relating to the incident. In addition, we have designated each November 13 as Safety Day. On that day, we host safety-focused meetings and activities at each complex and research facility, and invite relevant experts to address employees. Through these activities, we hope to instill in all our staff the determination to promote and ensure company safety.

Safety Day Activities (Fiscal Year 2023)

| Location |

Activities |

| Nanyo Complex |

Safety activity presentation |

Presentation on safety initiatives (November 11)

Three departments at the Nanyo Complex, and three collaborating companies of the Tosoh Group |

| Lecture on safety |

Safety management considers changes in social and business environment/Yokohama National University, Visiting Professor, Kazuhiko Noguchi(November 11) |

| Yokkaichi Complex |

| Headquarters |

| Tokyo Research Center |

Safety management that strives to achieve for Safety II / Technical advisor at Social Safety Research Institute, Shigeru Haga

(November 14) |

Safety Day: Safety activity presentation (Nanyo Complex)

Safety Day: Safety lecture (Yokkaichi Complex)

Safety Day: Safety lecture (Tokyo Research Center)

Safety monument: “Pledge of Safety” (Nanyo Complex)

Preservation and exhibition of accident-related documents (Nanyo Complex)

Initiatives to ensure safety

Enhancing risk assessment

With the aim of making risk assessment more comprehensive, we are reevaluating our security equipment from the standpoint of the multiple layers of protection proposed by Professor Emeritus Kimihide Matsuyama of Kyushu University.1 In addition, the Abnormal Reaction Information System (ARIS) is now in operation.2

At the Nanyo Complex, we verified the integrity of the third and final layer of protection (security, detoxification, and emergency shutdown equipment), and analyzed major events occurring in the security equipment by using fault tree analysis (FTA), taking into account multiple factors in the base layer and the first and second layers.3 Verification work on the functional integrity of security equipment has been completed in the production departments, with countermeasures being implemented for equipment deemed to be high risk.

Moreover, events determined to have a high impact factor—as in the risk of explosions, fires, and leaks—are reevaluated by adding multiple event analyses and quantification of risk assessment indicators. Additionally, the process of entering data into ARIS for plants subject to high-pressure gas certification has been completed. The results of the evaluation of reaction hazards are utilized in setting the key events of the FTA.

The Yokkaichi Complex is currently conducting a safety and disaster prevention risk assessment that incorporates perspectives on safety engineering and includes the verification of security equipment.

1. A system that consists of multiple tiers of plant accident prevention measures.

2. Abnormal Reaction Information System

3. Fault tree analysis (FTA) is a method for analyzing the causes of product failures and resulting accidents.

Improved education

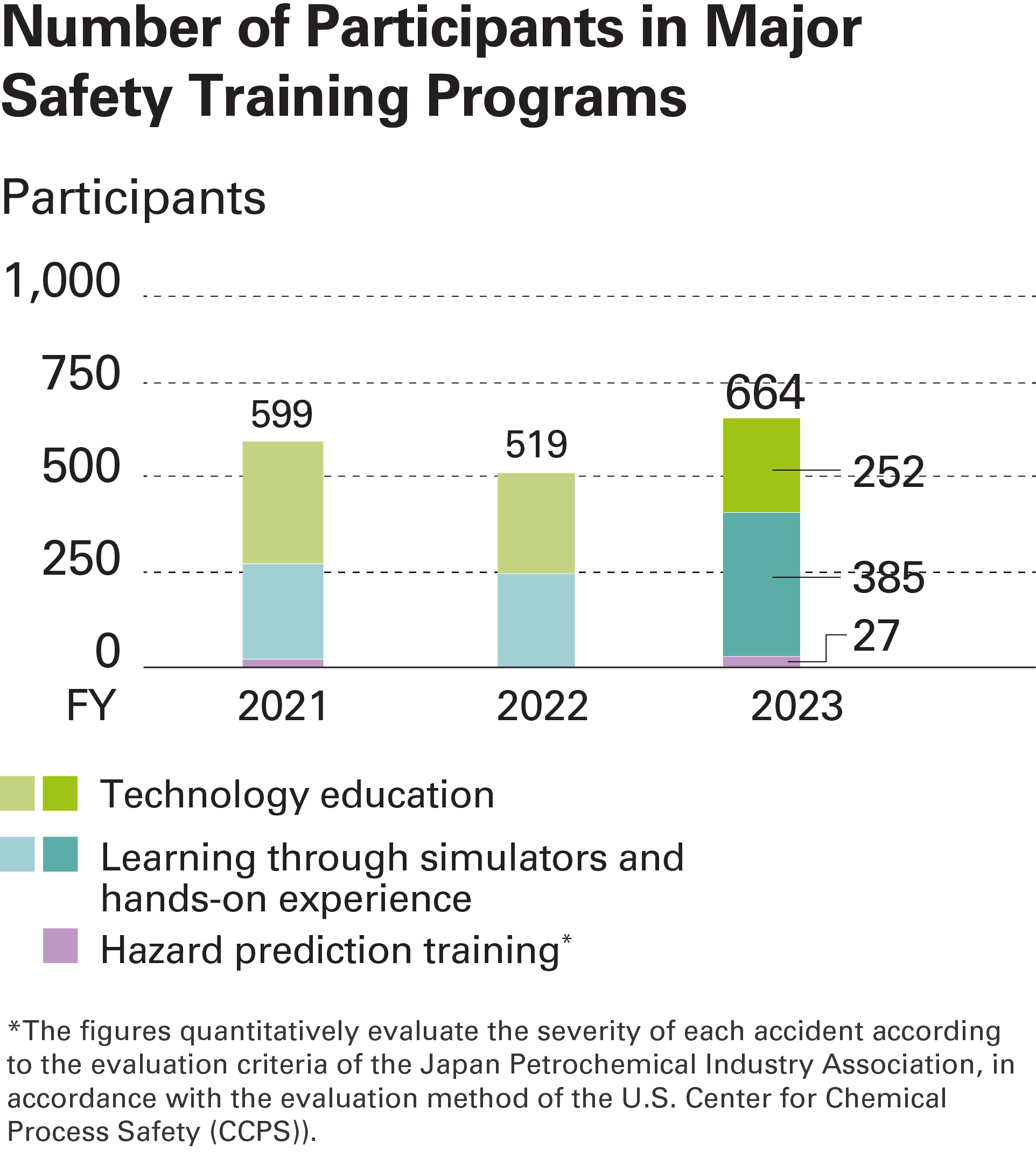

To achieve safe, stable, and efficient plant operation, we conduct a host of training programs in cooperation with related departments — these reflect the experiences and opinions of on-site employees. Technical education includes hazard experience training,1 and we also operate simulators and hands-on learning devices.2

In fiscal 2023, the company introduced equipment that allows visitors to experience how useful pointing and calling can be, as well as the fear of being deprived of oxygen. It further introduced hands-on equipment to enable experiencing climbing a rope ladder and being suspended in liquid.

We are striving to enhance education and training that enables employees to acquire knowledge and skills pertinent to safe and stable operations, and to improve our on-site capabilities. Training regarding protective equipment also covers the use of kit such as protective glasses, protective gloves, and helmets provided to individuals.

1. Practical training that allows participants to experience firsthand workplace hazards such as being caught or entangled in equipment, falling or being exposed to hazardous substances and static electricity.

2. Introduced in fiscal 2018, the facility allows visitors to experience the principles and characteristics of a distillation column—a fundamental operation of a chemical plant—how to start up and shut down a distillation column; and how to respond to abnormalities and other events.

Equipment for experiencing hazardous substance exposure and safety equipment operation

Virtual reality hazard simulation education

Protective equipment training

Equipment for experiencing oxygen deficiency

Equipment for experiencing climbing a rope ladder

Equipment for experiencing suspension in liquid

Accident case study research

To prevent the recurrence of accidents—and the issues that led to them—it is important to investigate their causes based on underlying principles, and then formulate and implement permanent countermeasures. To uncover the root cause of a given problem, Tosoh looks into why it occurred, and conducts detailed examinations and analyses of accident cases. In addition, we operate an accident and disaster information database to centrally manage such incidents. This facilitates our sharing of information and utilization of case studies for educational and training purposes.

Enhanced safety

Activation of digital transformation

We have been actively promoting the introduction of digital transformation (DX) to ensure plant safety and stable operations, and in June 2023 we established the Cyber Security DX Group as part of the IT Management Department to further promote DX. Moreover, we are working to establish a systematic training program that will rapidly develop human resources familiar with digital technology, such as data scientists, that are indispensable for advancing DX.

Implementation of common monitoring system for complexes

We are sequentially introducing a common monitoring system for our production departments, that utilizes big data accumulated in the distributed control system (DCS). Abnormalities can be quickly detected on the monitoring screen, and operational guidance is displayed on a large monitor located in the control room, enabling rapid and unified decision making.

Introduction of operational support system

The company has introduced an operational support system to visualize operational techniques and know-how in a flowchart format. In the form of a handbook, it is used for passing on operational techniques, education, and procedures. Furthermore, by automating operations through theory and principle—ones that were previously driven by empirical knowledge—safe, stable, and correct operations can be ensured.

Introduction of abnormality prediction and detection system

Tosoh has implemented a machine learning-based system for early detection of operational abnormalities. By machine-learning the correlations across plant data under normal conditions, rapid detection of abnormalities can be made based on the discrepancy between actual conditions and the obtained normal model. Machine learning is used not only for abnormality prediction and detection, but also for quality prediction and productivity enhancement. The Yokkaichi Complex has introduced diagnostics to predict and detect abnormalities in rotating equipment. Wireless vibration temperature sensors have been installed in key rotating equipment, while AI (enabling abnormality prediction and detection) and alarm reporting functions have been newly added to enhance condition monitoring functionality. (Test operation began in April 2023).

Electronic logbook for operational handover

Conventional handwritten operation handover logbooks have been digitized to provide electronic data on work history, operation information, and knowledge. This allows all parties involved to share information when retrieving past operational data, or for handover in a three-shift system, thereby improving efficiency. Moreover, facility management is optimized through the use of maintenance information links and mobile functions.

Implementation of tablets for on-site communication

We have introduced tablet devices for communication at production facilities. The system is used to support the work of younger employees, since information can be exchanged in real time between work site and control room through video and voice communication. At the Nanyo Complex, explosion-proof communication tablets have already been introduced at the polyvinyl chloride (PVC), electrolysis, and power plants.

These tablets have been issued to all members of the Facility Management departments at the Nanyo and Yokkaichi complexes, and are used to reduce travel time during repair work, share information in a timely manner, and improve work efficiency and quality.

Introduction of pocket cameras

In the Facility Management department, numerous wireless mobile cameras are deployed during periodic repair operations with the aim of reducing waiting time for construction personnel and to monitor work. In the production departments, the cameras are used to relay safety instructions from control rooms to operators and to confirm work status, contributing to safe, stable operation.

Introduction of wireless gas detectors

Tosoh has installed wireless gas detectors at the boundaries of its complexes, and toxic gas concentrations are monitored in real time via an internal network system. Employing wireless gas detectors with built-in batteries—that can detect gas leaks even during power outages caused by earthquakes—has enabled Tosoh to quickly and reliably assess the impact of gas leaks outside of its complexes, and to respond swiftly.

Introduction of wireless vibration and temperature sensors

Wireless vibration and temperature sensors are installed on rotating equipment over a wide area within the complexes, and vibration and temperature are monitored in real time via an in-house network system for early detection of abnormalities in rotating equipment. We are investigating the potential for accumulating vibration and temperature data to realize high-performance diagnostics for abnormality prediction.

Introduction of soft sensors

Variables within processes such as component concentrations, that are difficult to gauge with ordinary measuring devices, are automatically estimated in real time using machine learning. This makes possible continuous monitoring of such variables, facilitating early detection of process fluctuations and proactive operational responses.

Introduction of drones

The Nanyo Complex conducted tests of aerial and underwater drones during visual inspections of high locations such as chimneys and oxygen-depleted locations such as buried seawater pipes at power generation facilities. These confirmed that visibility is equivalent to that of in-person visual inspection and that drone-based visual inspection offers advantages over conventional methods in terms of safety, construction period, and cost. As such, we intend to utilize drones as an alternative to in-person visual inspections in similar situations. Moreover, we are working to apply the system to situation assessment at disaster sites.

In the Yokkaichi area, government and the private sector are together promoting initiatives related to the introduction of new technologies. Capitalizing on the characteristics of the region, we will introduce drones and train their operators to be able to perform high-elevation exterior visual inspections of tanks and other facilities as well as internal surfaces, and to rapidly assess damage in the event disaster strikes.

Installation of gas turbine energy management system

In conjunction with the construction of the gas turbine power plant, the company installed a system to collectively monitor the entire plant’s power and fuel balance, and calculate the optimal amount of gas turbine power generation. Adjusting operation based on the results of these calculations leads to higher efficiency, which in turn leads to energy savings.

Strengthened response to cyberattacks

In the interest of preventing security incidents and maintaining stable operation, it is essential to strengthen security measures against cyberattacks. Therefore, in addition to information systems, a firewall has also been installed on the control system network to which the DCS and other systems are connected, improving the ability to prevent both IT and OT (operational technology) computer virus infiltration.

Moreover, we have established a company-wide Cyber Security Committee to confirm facility soundness, formulate countermeasures, construct systems and PDCA cycles, and handle training of personnel.

Use of cloud-based storage

We use BOX cloud-based storage as a means of sharing information internally. It is also useful for stimulating interdepartmental collaboration, as well as that with external entities. The adoption of cloud-based storage also aids business continuity planning (BCP) and the prevention of data leaks to unauthorized external parties.

Electronic logbook for operational handover

Tablet for on-site communication

Monitoring with wireless gas detectors

Drone-based visual inspection of elevated areas (Nanyo Complex)

Drone-based inspection of the inner surfaces of storage tanks (Yokkaichi Complex)

Safety technology initiatives

To further improve the level of safety and promote process safety, the Safety Engineering team of the Technology Center is taking the lead in introducing safety technology, based mainly on safety engineering.

Advanced, comprehensive risk assessment

We have adopted the concept of multilayer protection for process safety evaluation, and have implemented numerous measures to raise the level of safety and thus prevent plant accidents. As a risk assessment method, we have established an advanced, comprehensive risk assessment system by adding FTA and abnormal reaction analysis to conventional methods, which are mainly based on hazard and operability studies (HAZOP).*

Training of safety technology experts

We are developing a curriculum to train safety technology specialists. Moreover, beginning in fiscal 2022, as a means of cultivating experts in this sphere we have dispatched two staff members as contract researchers to universities with specialized safety engineering courses in fiscal 2022, and another two in fiscal 2023.

Others

- Promotion of safety technology and security equipment verification

- Operational support using machine learning and other methods

- Analysis of equipment materials for corrosion and other diagnoses

- Chemical and engineering technology education using practical training facilities

- Support for analysis of critical issues

*Hazard and operability studies (HAZOP) are means of anticipating the consequences of events that impede operations and ensuring that the necessary preparations can be made.

Emergency response

Disaster preparedness training

Tosoh conducts disaster drills at each of its complexes, laboratories, headquarters, and branch offices to raise employees’ awareness of their responsibilities, and to equip them with the ability to respond to emergencies, thereby preparing them for unforeseen situations. Comprehensive disaster drills conducted in partnership with local government are also open to local community associations, not only for hypothetical accidents such as leakage and fire, but also for the evacuation that would be necessitated by a large-scale earthquake or tsunamis. Moreover, the computerization of the entrance and exit gates has created a management system to control entry to the premises in the event of an emergency.

At each plant, emergency shutdown response, emergency response to oil spills including the deployment of oil fences, hose deployment and water discharge for initial firefighting, and training in wearing protective equipment such as air respirators are regularly conducted based on documented procedures to improve on-site response and prepare for emergencies. Furthermore, a public relations system has been prepared for the event of an accident, based on the Public Relations Manual for Residents in the Event of Petroleum Complex Disasters. We have also prepared product-specific booklets on contingency plans and precautions to be taken in the event of an emergency in the region. Annually, we invite media representatives to give mock press conferences and practice lectures, to bolster risk communication skills.

Comprehensive disaster preparedness drills at Yamaguchi Prefecture petroleum complex (Nanyo Complex)

Comprehensive disaster preparedness drills (Yokkaichi Complex)

Comprehensive disaster preparedness drills (Tokyo Research Center)

Society Safety Day activities table

| Name |

Date implemented |

Location |

No. of participants |

Details |

| H1 comprehensive disaster drills |

July 2022 |

Nanyo |

100 |

A disaster drill simulating a massive earthquake |

| Comprehensive disaster drills |

October 2022 |

Headquarters/Yokkaichi |

145 |

A disaster drill simulating a Nankai Trough earthquake and the subsequent hazardous material leaks and fires causing plant outages, as well as blackouts and tsunamis.

Disaster prevention drones introduced to improve information gathering capabilities. |

| Comprehensive disaster drills |

October 2022 |

Tokyo Research Center |

525 |

Conducted blind drills together with the Ayase City Fire Department.

Simultaneously set up a large tent and practiced handing out emergency rations. |

| H2 comprehensive disaster drills |

November 2022 |

Nanyo |

350 |

Conducted in conjunction with the comprehensive disaster prevention drills of other petrochemical complexes in Yamaguchi Prefecture. Drills conducted concerning resident evacuation, and onshore and offshore drills simulating a massive earthquake.

Drones were employed to monitor the situation, with live images shown at the disaster prevention headquarters and to guests. |

| Blind comprehensive disaster drills |

November 2022 |

Yokkaichi |

185 |

A blind disaster drill simulating fires at plants caused by hazardous material leaks |

| Drills by complex |

Practiced throughout the year |

All complexes |

- |

Emergency plant shutdown, water cannon training, and protective equipment fitting drills.

Water cannon training conducted jointly with the Disaster Prevention Center. |

Earthquake and tsunami countermeasures

In addition to evacuation and other response drills, we are also working on equipment handling. As earthquake countermeasures, we completed all seismic reinforcement work for high-pressure gas storage tanks at the Nanyo and Yokkaichi complexes. In fiscal 2023, we made progress on seismic reinforcement work for control rooms and offices where employees are stationed. In terms of tsunami countermeasures, we are installing raised floor-type electrical equipment and on-site display of flood levels.

On-site display of flood levels (Yokkaichi Complex)

Business continuity plan initiatives

Tosoh's first priority is to ensure the physical safety of employees under emergency circumstances, including widespread contingencies such as the COVID-19 pandemic. At each complex, we are implementing sequential steps to secure emergency power sources, safely shut down plants, and quickly restore operations in the event of a blackout caused by an infrastructure shutdown. To ensure a stable supply of products to our customers, we are optimizing inventory and promoting purchasing from multiple sources, and are also reviewing and strengthening our disaster countermeasure regulations.

In addition, due to our global business expansion, there is increased opportunity for our employees to travel and be posted overseas. This increases the vulnerability of Tosoh personnel to global events such as wars, earthquakes, terrorism, riots, and outbreaks of infectious disease. We are therefore implementing overseas crisis management measures to ensure the safety and well-being of our employees.

*A business continuity plan (BCP) is an action plan to maintain operations for as long as possible in the event of a disaster, accident, or other unforeseen event, and to recover and resume operations as soon as possible following an interruption.

External evaluation

In December 2017, the Nanyo Complex reacquired certification as a Specific Accredited Completion and Safety Inspection Executor and as an Accredited Completion Inspection Executor, underwent a certification renewal audit in August 2022, and renewal was completed in December. The Yokkaichi Complex renewed this certification in November 2021. Tosoh undergoes regular external evaluation by the Japan Industrial Safety Competency Center (JSCC), a non-profit organization, to improve the security capabilities of each complex. Preparations are also underway to apply under a new certification system. Moreover, in January 2023, the company established a Cyber Security Committee to assess the robustness of the Tosoh Group’s security and implement measures in accordance with this assessment.

Logistics safety

Basic concept

Tosoh's products are delivered to customers primarily by truck and ship. Since accidents during transportation can cause delays in deliveries to customers, damage to facilities, and other issues, we are actively working to eliminate such incidents.

List of RC Activity Target Results: Logistics Safety

Initiatives to eliminate logistics accidents

We are working to reduce the occurrence of accidents, and to improve safety awareness by implementing logistics-specific hazard prediction training and confirming its effectiveness through surveys.

Support for transportation equipment

We are also actively implementing hardware initiatives, such as initiating research into the prevention of contact accidents by installing work detection systems on forklifts.1

Support for sea transport

For ships, we conducted voyage and operation diagnoses as part of education for logistics subcontractors (13 vessels were examined in fiscal 2023), and followed up on the results of these examinations.2 Patrols are conducted on each vessel to confirm management status.

Response to road transport issues

We are considering responding to requests from our logistics partner companies to improve our lorry delivery facilities. And lorry filling station layouts at our complexes have been improved to lower the risk of accidents involving contact with and exposure to liquids.

1. A camera and sensor-equipped device installed on forklifts to detect approaching people and alert them with lamps or buzzers.

2. A third-party instructor should be present during the actual voyage to confirm and evaluate the crew's judgment and knowledge.

Occupational safety and health

Basic concept

Under the RC promotion system, the Tosoh Group always recognizes that "safety takes precedence over everything else" based on its basic philosophy of environment, safety, and health, and is working to ensure safety with the aim of zero lost work time accidents involved in the Group's operations. With the aim of eliminating unstable conditions and unsafe behavior that can lead to industrial accidents, Tosoh will develop safety activities based on five pillars: Comprehensive implementation of basic safety measures, improvement of risk assessment comprehensiveness, making efforts to eliminate similar incidents and industrial accidents, reinforcement of construction systems, and utilization of new technologies, and foster a culture of safety.

List of RC Activity Targets and Achievements: Safety Disaster Prevention and Occupational Health and Safety

Fiscal 2023 results

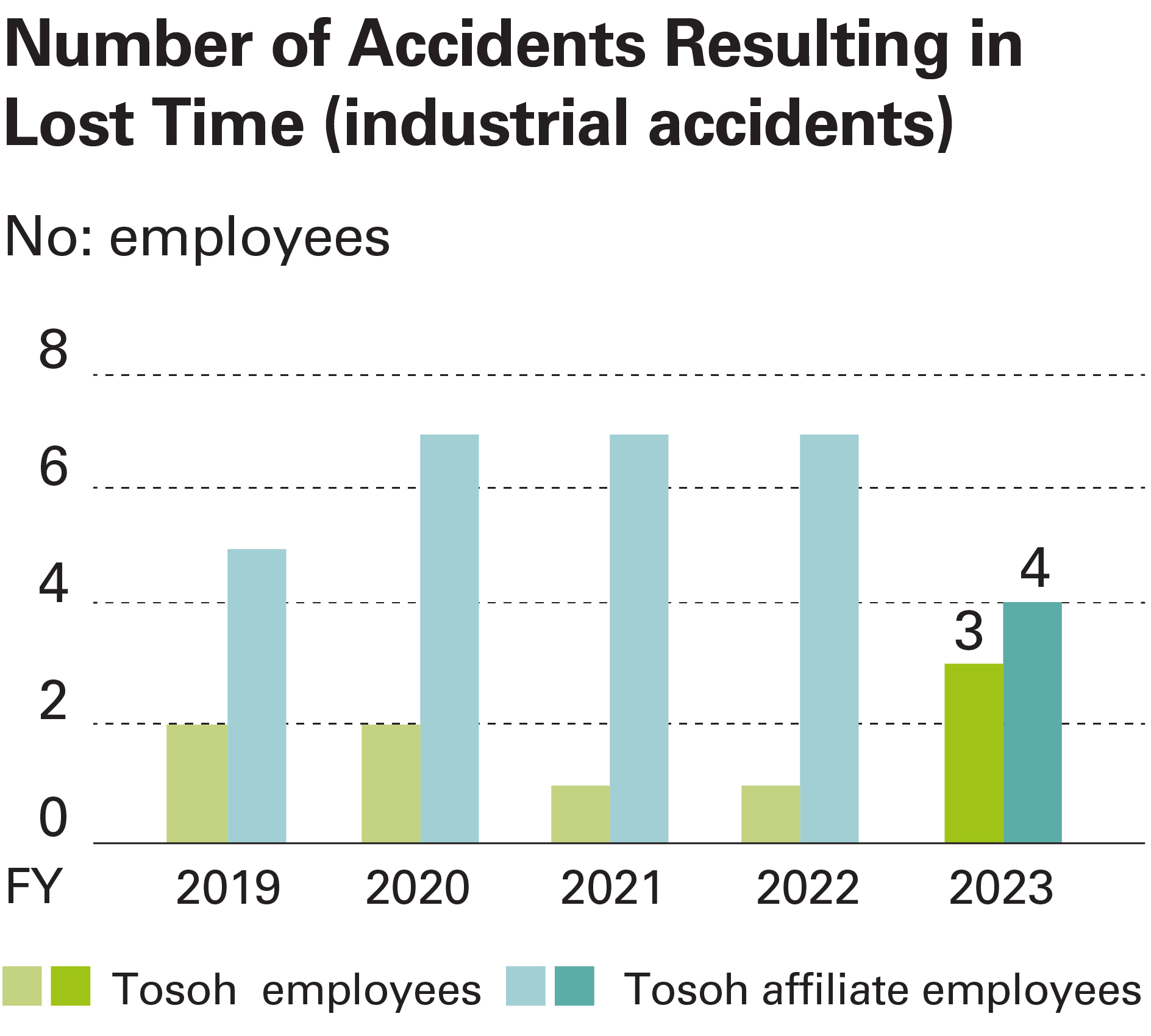

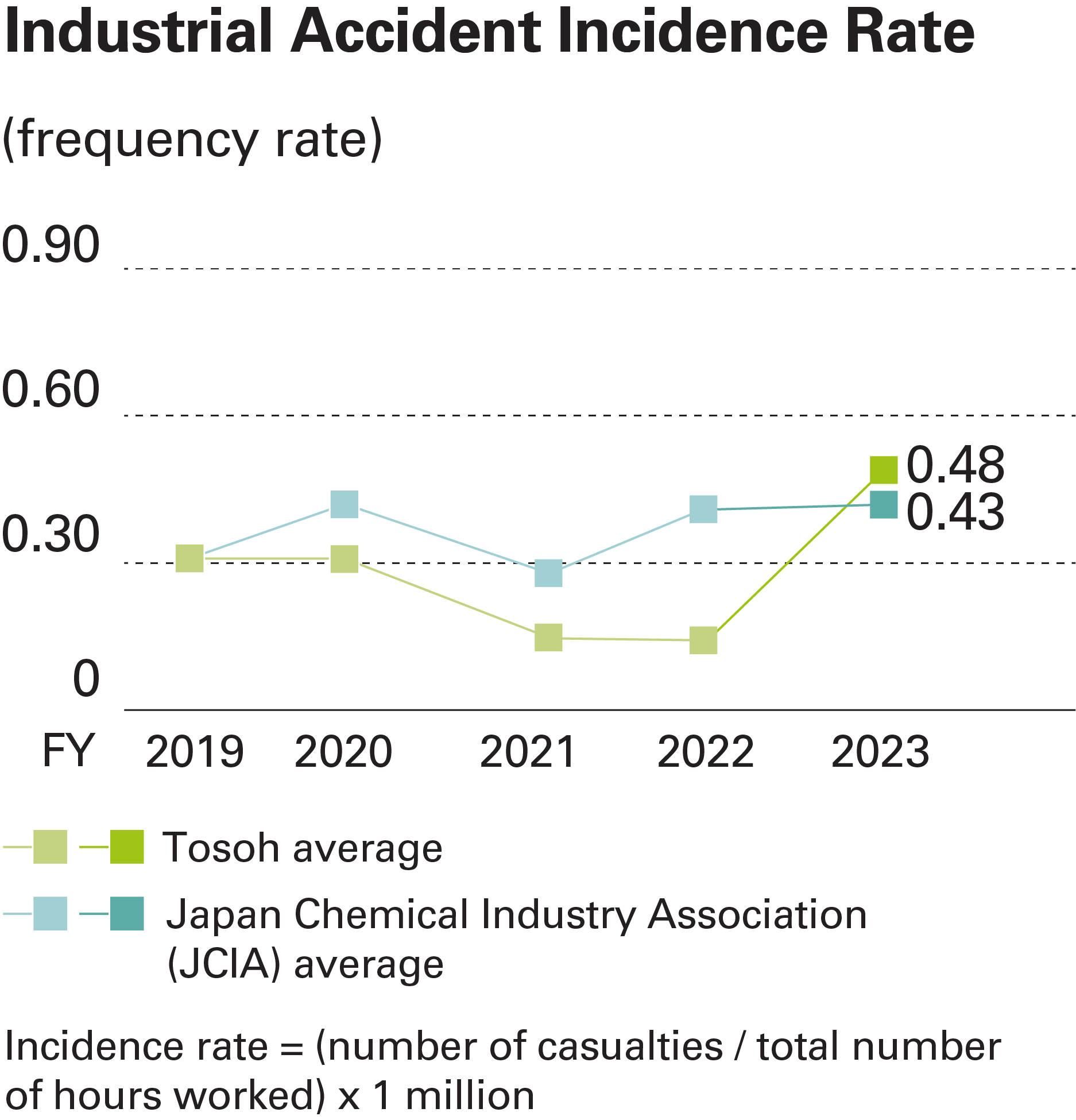

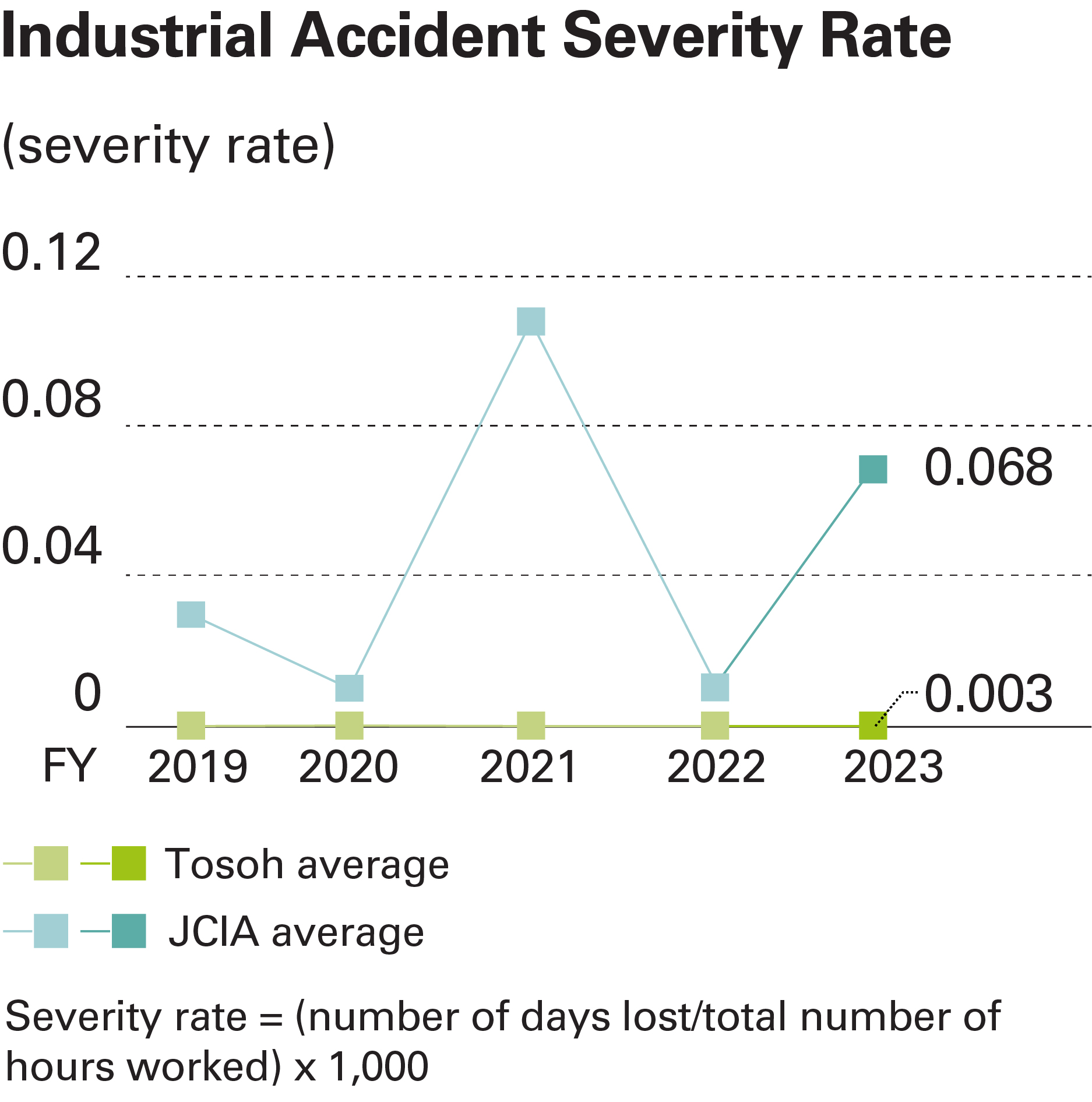

Tosoh has set a target of zero accidents resulting in lost time for employees and subcontractors. In fiscal 2023, 7 lost time accidents (3 employees and 4 at subcontractors) occurred, so we did not achieve our goal. The causes of accidents resulting in lost time included inadequate equipment maintenance procedures among employees and non-compliance with basic operations and lack of attention among subcontractors. As a measure to prevent recurrence, we hold Safety and Health Committee meetings at our complexes to share and horizontally disseminate information on workplace accidents, and use incident investigation check sheets and other tools to more thoroughly delve into causes and countermeasures. We will continue to reconfirm work procedures, thoroughly implement hazard prediction procedures, and upgrade equipment.

In addition, 13 accidents (10 employees and 3 at subcontractors) resulting in lost time occurred at Group companies in fiscal 2023. We share information through the Accident and Industrial Accident Information Database and utilize outside safety specialists from the Japan Industrial Safety & Health Association to provide safety guidance and prevent recurrence.

Topics

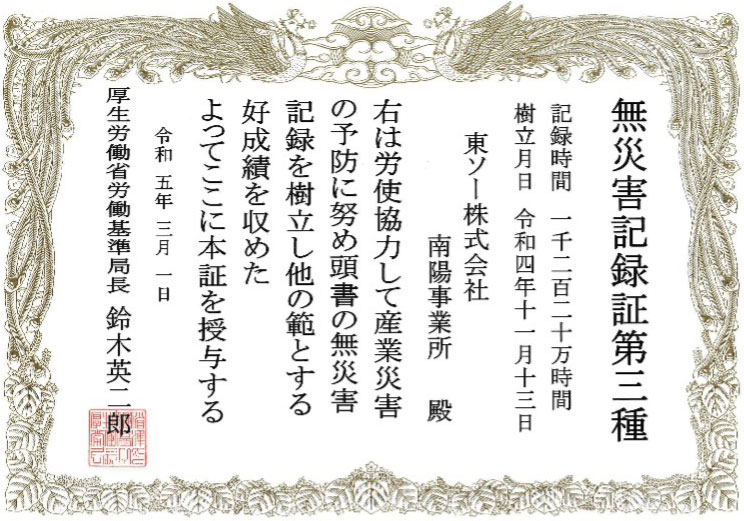

Received a Class-3 accident-free record certificate

As a result of proactive safety promotion efforts, the Nanyo Complex has maintained a record of zero injuries causing lost worktime over a total of 12.2 million hours worked by all employees, earning a Class-3 Accident-Free Record Certificate from the Labor Standards Bureau of the Ministry of Health, Labour and Welfare. Large complexes rarely achieve such a milestone, and it is the first time the Nanyo Complex received this award, which is a great honor and a tangible result of our past safety promotion efforts.

Fostering a culture of safety

5S* activities and RC Committee 5S inspections

Tosoh’s Nanyo and Yokkaichi Complexes and research facilities participate in the 5Ss*—sort, set in order, shine, standardize, and sustain. This keeps work environments clean and orderly and makes it easy to detect irregularities in our complexes and equipment. The Nanyo Complex has designated the third Wednesday of each month as Plant Safety Promotion Day. All divisions join in cleanup efforts, and the headquarters’ administrative division cleans up areas outside the complex premises as part of its contribution to the community. The Yokkaichi Complex is working to improve coverage by restructuring the general patrol area from 10 to 12 locations, making the area checked per person smaller and more precise. In addition to improving all areas where safety is in question at work sites, the Nanyo Complex has identified good practices and shared them across the Group.

The RC Committee chairperson conducts 5S inspections based on the policy that it is important for management to evaluate safety measures in the field and identify issues that need to be improved to maximize safety. Although the program was canceled in fiscal 2023 due to COVID-19, the continuation of the evaluation and recognition was addressed through document audits, as it would lend continuity to the activity and heighten employee motivation. The RC Committee chairperson presented certificates of recognition to workplaces eligible for 5S activity excellence awards (two at the Nanyo Complex, and two at the Yokkaichi Complex).

5S Activities: Cleaning off premises (Nanyo Complex)

5S activity improvement (document management) case study

5S Activities: Painting safety corridors in-house (Yokkaichi Complex)

5S Activities: Outstanding workplace commendation (Yokkaichi Complex)

Hazard prediction activities

The Tosoh Group’s complexes and research facilities work independently to establish hazard prediction training. The Nanyo Complex has revised its non-routine work standards and introduced pull-down hazard prediction to increase familiarity with them. Meanwhile, the Yokkaichi Complex has implemented 1R-specific hazard prediction training and is working to thoroughly strengthen one-person hazard prediction and other activities.1 Moreover, we provide new employees with hazard prediction training sessions led by outside instructors that focus on the necessity of anticipating potential danger. 2 The Tokyo Research Center is also promoting the establishment of one-person hazard prediction. At each of Tosoh’s locations, a self-motivated attitude has taken root through ongoing activities.

1. Training to improve skills to identify hazardous sources.

2. Hazard prediction activities are conducted by each worker on an individual basis when he or she is about to begin work.

Hazard prediction activities (Nanyo Complex)

Hazard prediction training session (Yokkaichi Complex)

Group discussions during hazard prediction training (Yokkaichi Complex)

Tosoh group initiatives

To strengthen its capabilities in disaster prevention and occupational safety and health, the Tosoh Group established the Tosoh Group Safe Work Environment Network, which improves our ability to share amendments to legislation, data on accidents, and other relevant information. One of the main initiatives are Safe Work Environment Network Meetings, which are held twice annually to bring together safety and health management representatives from Group companies for the purpose of information exchange and interaction.

In fiscal 2023, Tosoh held two environmental education sessions led by external trainers. It also conducted four other sessions on occupational safety and health education to improve the level of safety. In addition, it conducted Safe Work Environment Network Meetings where personnel from the Environment, Safety, & Quality Control department at Tosoh headquarters visited 9 companies to check on sites and exchange opinions. And the company continues to provide workplace guidance via third parties with the aim of creating opportunities to gain awareness from new perspectives.

Safe Work Environment Network Meetings (online)

Occupational safety and health education (online)

Safety environment exchange

Topics

Received an honorable mention from the Toyama Labor Bureau

Tosoh Ceramics received an honorable mention in the 2023 Toyama Labor Bureau awards.

The Toyama Labor Bureau gives its awards in recognition of good corporate safety and health results and improvement efforts that serve as a model for others.

We received an honorable mention for our hazard prediction and other safety training courses for all employees and our safety meetings.

Initiatives toward ensuring safety

Reinforcement of construction system

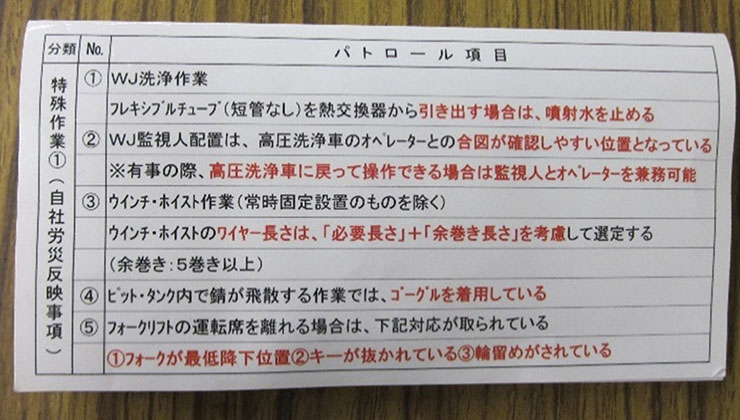

Tosoh is also promoting measures for incidents and industrial accidents involving subcontractors (construction companies) as part of its efforts to reinforce the construction system. In fiscal 2023, we verified the existence of systemic deficiencies based on work-related accidents that occurred on the Construction System Mechanism Verification Sheet. As we manage the verification sheet, we will continuously work to improve the construction management system. Moreover, the Nanyo Complex implemented initiatives to improve the level of subcontractors. Measures included distribution of one-person hazard prediction cards by job classification, hazard experience training, and flange connection technique certification. The Yokkaichi Complex revised its considerations for ideal on-site patrols, created new points for confirmation in reviewing work quality, and took initiatives such as distributing pocket guides on complex regulations to subcontractors.

Cover page of considerations for ideal on-site patrols (Yokkaichi Complex)

Key office regulations (Yokkaichi Complex)

Ensure safety of contracted work on site

Tosoh Logistics Corporation, a group company that outsources contract work such as packaging and filling at its Nanyo and Yokkaichi complexes, is promoting activities to eliminate occupational accidents at its subcontractors, surveying dangerous areas and implementing safety measures in cooperation with the production departments. In fiscal 2022, the Nanyo Complex selected a model workplace to sort out problems in the subcontractor work system, and in fiscal 2023, the complex is expanding its activities to other contracted workplaces in addition to the model workplace. In addition, regular monthly meetings with Tosoh are held to clarify the workflow and scope of outsourced work, and to identify and improve hazardous areas. To prevent accidents from occurring in the first place, the Yokkaichi Complex reviewed case studies of accidents from the past five years, and conducted monthly training sessions based on these findings. It reworked on-site patrols from the previous approach of primarily pointing out hazardous areas to asking workers for their input during patrols.