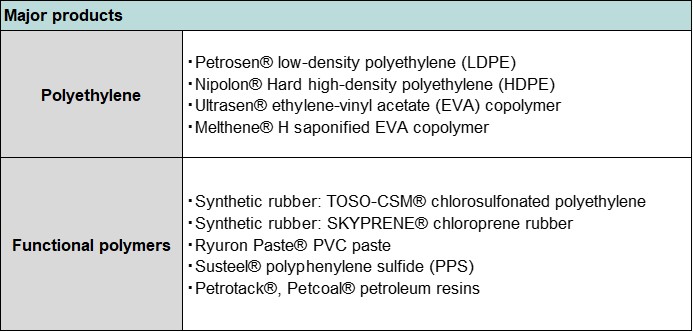

Tosoh always aims to operate a unique, distinctive business. Therefore, we offer products that satisfy broad-ranging needs while carefully integrating polyethylene and functional polymers into a variety of different business domains.

Business Vision

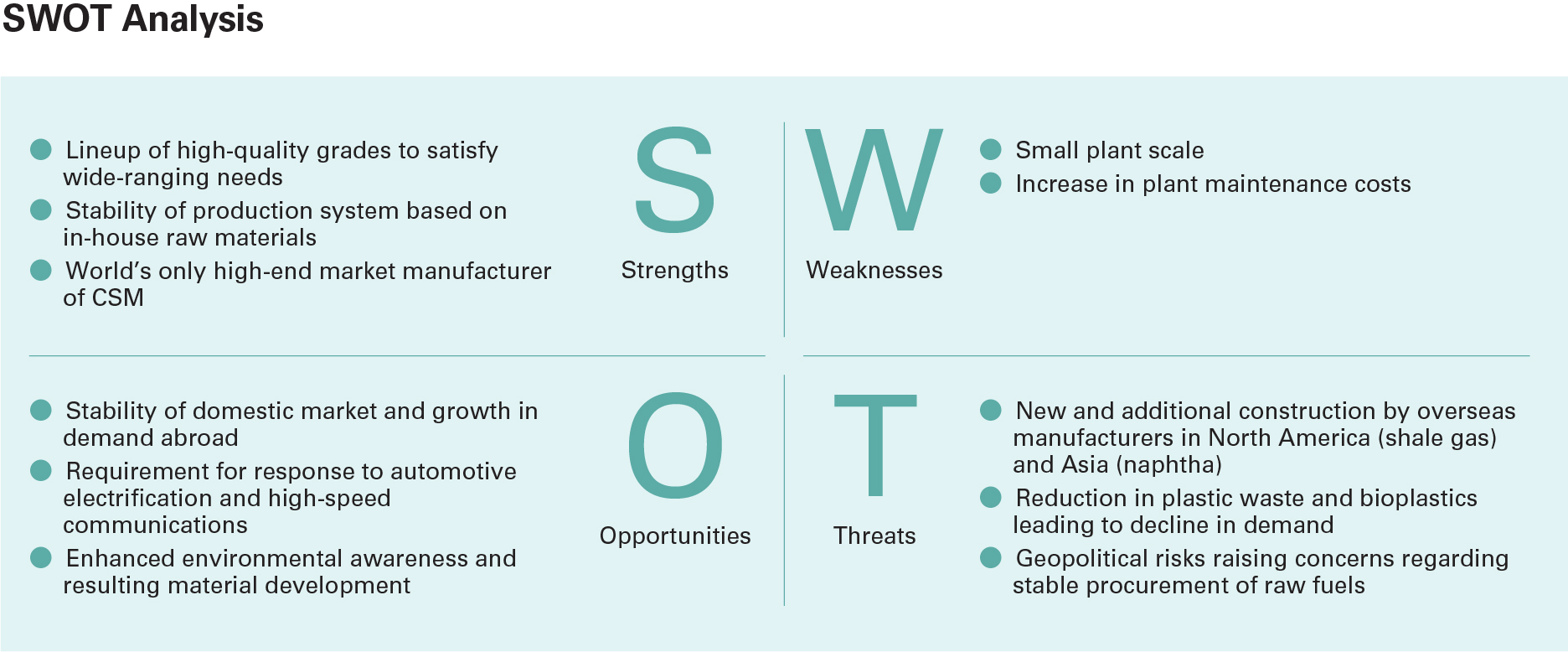

In response to the challenging business environment that has resulted from the global trend toward decarbonization and de-plasticization, Tosoh has identified three priority themes: stable operations and supply, differentiation and higher-added-value, and environmental response.

The focus on differentiation and higher-added-value will further deepen functions and performance in applications that have traditionally been the company’s strengths. Under the theme of environmental response, we will continue developing and expanding sales of products that improve plastic recyclability, as well as products for the electric vehicle (EV) market.

While maintaining a strong awareness that plastics are essential materials for our daily lives, Tosoh will continue working hard to satisfy increasingly diverse user demands.

Medium-Term Business Policy (FY2023–FY2025)

Polyethylene

- Differentiate, and ensure higher-added-value

- Increase base sales price to expand earnings

Functional polymers

- Increase production capacity in growth areas

- Expand applications to grow market share

World’s top share—Synthetic rubber CSM

Susteel® polyphenylene sulfide (PPS)

Medium-Term Business Policy Initiatives

Polyethylene Business Initiatives

Capitalizing on the product's superiority in terms of cleanliness, low odor, and low off-flavor properties, Tosoh plans to further boost its market share in the food packaging, medical, and semiconductor fields—areas in which the company has traditionally excelled—and will invest more in the construction of a stable supply system. The company will fully leverage its proprietary catalyst and compounding technologies to not only satisfy user requirements but also grow our product lineup. And in support of recycling plastic and the reducing of plastic waste, we will actively promote the development of products utilizing all of the technology and experience we have acquired. Tosoh will also continue collaborating with brand owners to deliver products that contribute and benefit society.

Toward Specialty Business Operating Income in Excess of ¥100 Billion

Tosoh intends to grow its supply structure through planned functional polymer capacity expansion and accelerate environmentally friendly product R&D in response to policies related to the electrification of vehicles to further expand earnings. And, in the interest of establishing a stable supply system and expanding our market share, the company will steadily implement capacity increase plans related to our mainstay synthetic rubbers, chloroprene rubber (CR), and chlorosulphonated polyethylene rubber (CSM) products. Tosoh will also develop and expand sales of environmentally friendly products such as CR augmented with carbon nanofibers.

Products Certified as Solutions to Social Issues

・Ethylene-vinyl acetate (EVA) copolymer for encapsulation of solar cells

For more details, please visit: Social Issue Solutions

Differentiation Strategies

Making Polyethylene More Environmentally Friendly

Recycling aids, mono-materialization, thin-film, integration with paper, and more

Tosoh developed Melthene as a functional resin that is modified both chemically and physically to add higher value to EVA and promotes it as a practical EVA offering exceptional adhesive properties.

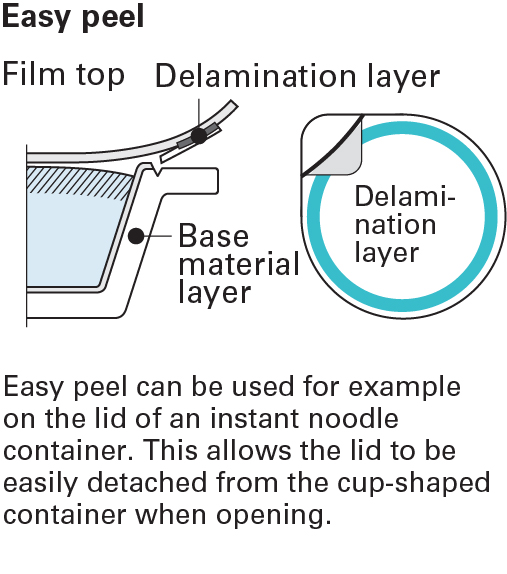

Users have praised Melthene M for its excellent adhesive properties and easy peel* material that easily peels off from the base material. The company is also developing Melthene H, which is EVA saponified with caustic soda, for other resin modification applications by capitalizing on its specific molecular structure.

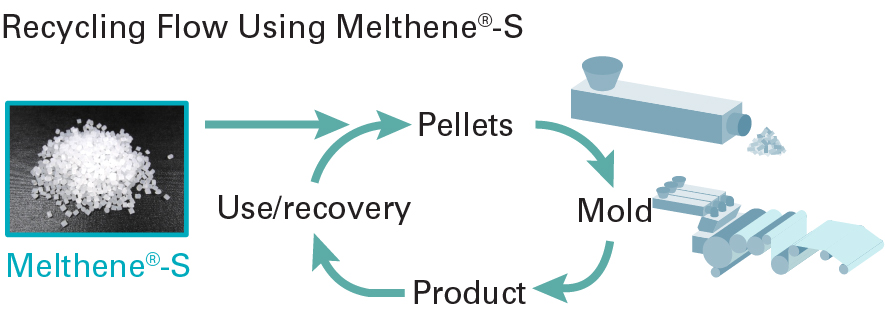

Amidst the active promotion of the material recycling of plastics, Melthene-S is being used as a plastic recycling aid in product development to enhance plastic composite material recyclability. Tosoh will, therefore, continue its emphasis on product development to further contribute to the resolution of a variety of social issues.

Environmentally Friendly Automobile-Related Products

Tosoh considered entering into the engineering plastics business—where it anticipated growth—and launched production of polyphenylene sulfide (PPS) in Japan for the first time in 1986. With noticeably superior characteristics such as heat resistance, rigidity, and dimensional stability, PPS is now widely used in various applications, including automotive parts as well as electrical and electronic components. The company believes the continuing trend toward the transition to EVs should boost demand for electrical components. Given this, Tosoh is developing numerous grades of its PPS for automotive applications by capitalizing on the product’s superior metal bonding properties.

S High-Quality Grade to Satisfy Broad-Ranging Needs

At Tosoh, we believe it is not only important, but indeed our responsibility as a manufacturer, to provide products that meet and satisfy user needs. Although the company does support the option of trimming its product lineup to boost production efficiency, pursuing the tailoring of products to meet such needs will boost customer satisfaction while also enhancing our development and technical capabilities, and we intend to adhere to this policy. And as user needs and demands become increasingly diverse, we will remain diligent in our efforts to develop products and further enhance our lineup.

O Growing Environmental Awareness and Corresponding Material Development

Looking at polyethylene, Tosoh is working hard to reduce the use of plastic in all food containers and other products by either employing thinner films or instead using paper when possible to reduce weight. To improve recyclability, we focus on plastic recycling aids and shifting from plastic composite to mono-materials.

In the area of functional polymers, the company is augmenting the development of metal-bonded PPS for electrical components for EVs. In response to the increasing weight of vehicles due to the transition to EVs, we are actively advancing the development and application of petroleum resin as a performance enhancer for fuel-efficient tires.