Addressing Climate Change Issues

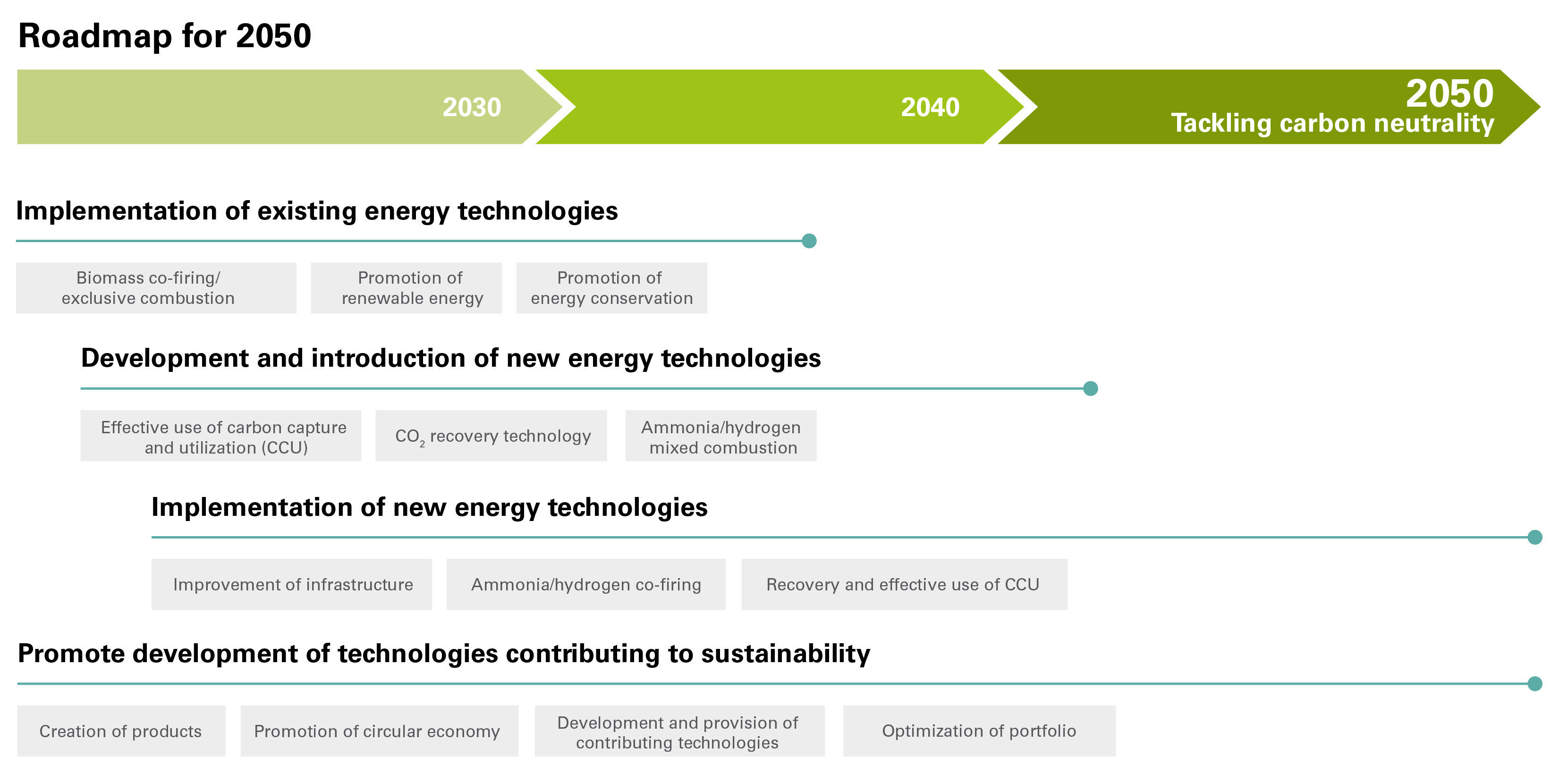

Climate change is one of the world's most pressing societal issues. Accordingly, the Tosoh Group recognizes that contributing to the reduction of greenhouse gas (GHG) emissions through its business activities is a key focus for the company’s medium- to long-term growth, and is promoting the reduction of CO2 emissions through energy conservation and fuel conversion, as well as the study of technologies for the effective utilization of CO2.

Basic Concept

In October 2020, the Japanese government declared its intent to achieve a decarbonized society by 2050. In response, Tosoh in 2022 established a new GHG emissions reduction policy for the entire group.

New Policies

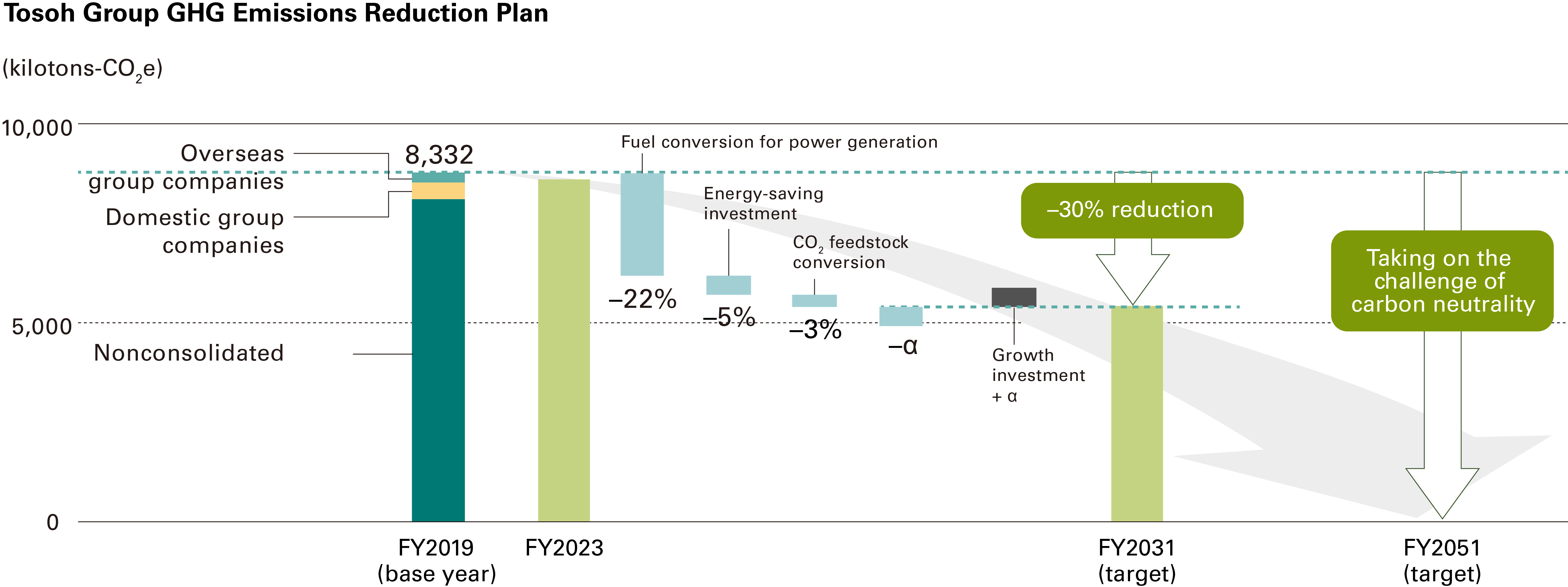

- Cutting GHG emissions (Scope 1+2) by 30% compared with fiscal 2019, by fiscal 2031

- Working toward becoming carbon neutral by 2050

CO2 discharged by energy sources accounts for the majority of Tosoh's GHG emissions. Tosoh has been actively investing in energy conservation ahead of schedule while working aggressively to mitigate these emissions. The company will promptly implement various measures toward a decarbonized society, taking into account trends in Japan's energy policy; the policies of industry associations; technological innovations; and the distribution of CO2-free fuels.

Tosoh also endorsed the Task Force on Climate-related Financial Disclosures Task Force (TCFD*1) recommendations in November 2019. In line with these recommendations, the group will continue to disclose information on its initiatives. Moreover, we aim to fully disclose our CFP*2 upon calculating and verifying our figures in response to societal demand.

1. Task Force on Climate-related Financial Disclosures: The Financial Stability Board established this organization to formulate a disclosure framework that aids in understanding climate-related risks and opportunities for companies. In June 2017, Tosoh published recommendations related to items of information disclosure.

2. Carbon Footprint of Products: A framework for communicating through easy-to-understand CO2 measurements the GHG emissions generated by products and services throughout their entire life cycle, from raw material procurement to disposal and recycling.

Measures to Cut GHG Emissions

- Promoting energy conservation

We convert changes in GHG emissions from new investments to expenses using an internal carbon price as a basis for investment decisions. We will raise this internal unit price to 6,000 yen/ton-CO2 to accelerate energy conservation efforts as never before.

- Decarbonizing the energy we use

Our biggest target for reducing GHG emissions is through cutting CO2 discharged by in-house thermal power generation facilities. We will promote a gradual transition from coal and other fossil fuels with high GHG emissions, to biomass, ammonia, hydrogen, and other clean energy sources, while simultaneously bolstering our efforts to introduce renewable energy sources, such as solar power, to eliminate carbon from the energy we use.

- Recovering and effectively utilizing CO2

With support from external research institutions and the government, we promote the development of technologies to separate and recover CO2 emitted by power generation facilities and manufacturing processes then effectively use it as a raw material for polyurethane and other products.

- Investing in measures to cut GHG emissions

In addition to ongoing capital investments, we plan to spend approximately ¥120 billion in cutting GHG emissions by fiscal 2031 to support measures 1–3 above. This spending includes a plan to invest approximately ¥60 billion over three years starting in fiscal 2023, the most recent fiscal year.

Disclosing Information Based on TCFD* Recommendations

*Task Force on Climate-related Financial Disclosures

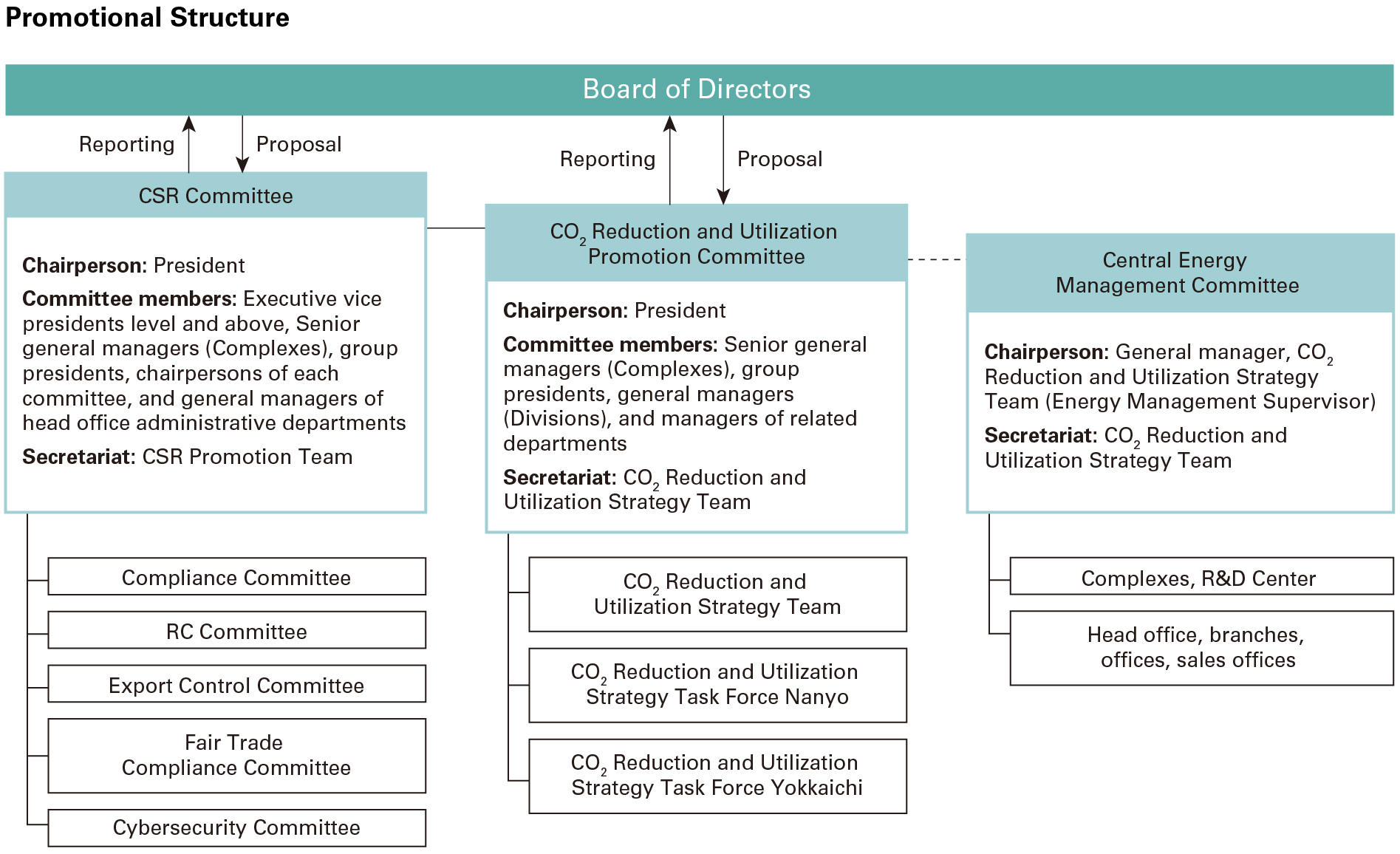

Governance

Tosoh’s response to climate change issues is promoted mainly by the CO2 Reduction and Effective Use Promotion Committee and the Central Energy Management Committee. We are also gathering information on social trends, regulatory requirements, and climate change-related risk management and sharing this information with companies across the Tosoh Group. Matters relating to these activities are reported to the respective Board of Directors for approval as appropriate, with necessary instruction then received.

Promotion Systems

Promotion Systems

CSR Committee

Corporate Social Responsibility (CSR) has gained prominence in recent years. The Tosoh Group recognizes that helping address various social issues—including climate change—through its business activities is vital for sustainable growth. Thus, we promote our business with CSR at the heart of management.

Chaired by the representative director and president, our CSR Committee deliberates on key matters relating to the Tosoh Group’s CSR activities. The committee reports its resolutions to the Board of Directors for approval and instruction as necessary. Moreover, we have established organizations to promote specific responses to climate change issues under the CSR Committee: the CO2 Reduction and Effective Use Promotion Committee, the Responsible Care (RC) Committee, and the Central Energy Management Committee.

We have identified climate change as an essential CSR issue the Tosoh Group should address. The representative director and president, who chairs the CSR Committee, is responsible for climate change-related policy. Our new president took office in March 2022, taking over the above-mentioned responsibilities while retaining his prior role as chair of the CO2 Reduction and Effective Use Promotion Committee, thus broadening his climate change-related responsibilities.

In fiscal 2023, we confirmed our fiscal 2022 progress toward our energy-derived CO2 emission reduction target, a key performance indicator (KPI) for climate change-related issues. We resolved to adopt a new KPI for the next three years, along with a four-year summary. We also formulated a new GHG emission reduction policy to become carbon neutral by 2050.

Activities and discussions (reports) for fiscal 2023

- Essential CSR issues set for fiscal 2023–fiscal 2025 (to be submitted to the Board of Directors)

- KPI progress assessment for fiscal 2022 and fiscal 2023 action plan proposal

Related pages: Essential CSR issues

CO2 Reduction and Effective Use Promotion Committee

The committee is chaired by the director in charge (president and representative director after March 2022), and promotes identifying issues, formulating policies, conducting research and analysis, and advancing emission reduction management. This includes transitioning to alternative fuels and effectively using CO2 through its recovery and conversion into raw materials. These efforts actively promote reducing and effectively utilizing energy-derived CO2 emitted from in-house thermal power plants.

In June 2021, the CO2 Reduction and Effective Use Strategy team and the CO2 Reduction and Effective Use Task Forces at the Nanyo and Yokkaichi complexes were established to strengthen the system for promoting CO2 reduction and effective use.

- CO₂ Reduction and Effective Use Strategy team: Newly established under the CO₂ Reduction and Effective Use Promotion Committee to formulate company-wide strategies, collect information on government trends, and coordinate with the task forces at the Nanyo and Yokkaichi complexes.

- CO₂ Reduction and Effective Utilization, Nanyo and Yokkaichi Task Forces: These task forces have been newly established at the Nanyo and Yokkaichi complexes to implement specific measures at each site. The task forces also belong to the CO₂ Reduction and Effective Use Promotion Committee to coordinate throughout the company.

Activities and discussions (reports) for fiscal 2023

- Activity report for fiscal 2023 (including the biomass power plant installation and GI fund business)

- Discussions on formally joining the GX League

- Discussions on criteria for installing solar power plants

Central Energy Management Committee

The committee, chaired by the head of the CO₂ Reduction and Effective Use Strategy team, is working to achieve comprehensive energy savings. This includes improving energy consumption in production and transportation, and promoting alternative energy sources. Specifically, the committee discusses and determines policies for energy management, medium-term and annual plans, compliance status and evaluation methods, and energy management-related matters.

Activities and discussions (reports) for fiscal 2023

- Review of the previous fiscal year’s energy use results and initiatives and policies for fiscal 2023

- Communication on the Energy Conservation Act revisions (promoting the use of non-fossil fuel energy) with the response plan

CSR Advancement Liaison Meeting

The Tosoh CSR Advancement team serves as the secretariat, sharing information on climate-related social trends and exchanging opinions with the aforementioned committees on compiling group-wide GHG emissions data.

Strategy

Scenario analysis

Scenario analysis predicts how business conditions will change due to both climate change and the long-term trends in government policy addressing the issue. It also examines how such changes will impact our corporate business strategies. Through scenario analysis, the Tosoh Group discovers the likely impact of risks and opportunities relating to climate change issues. It incorporates these lessons into its medium- and long-term management plans, formulating strategies to further promote our products, technologies, and services that contribute to addressing the issues that must be tackled in order to realize a sustainable society.

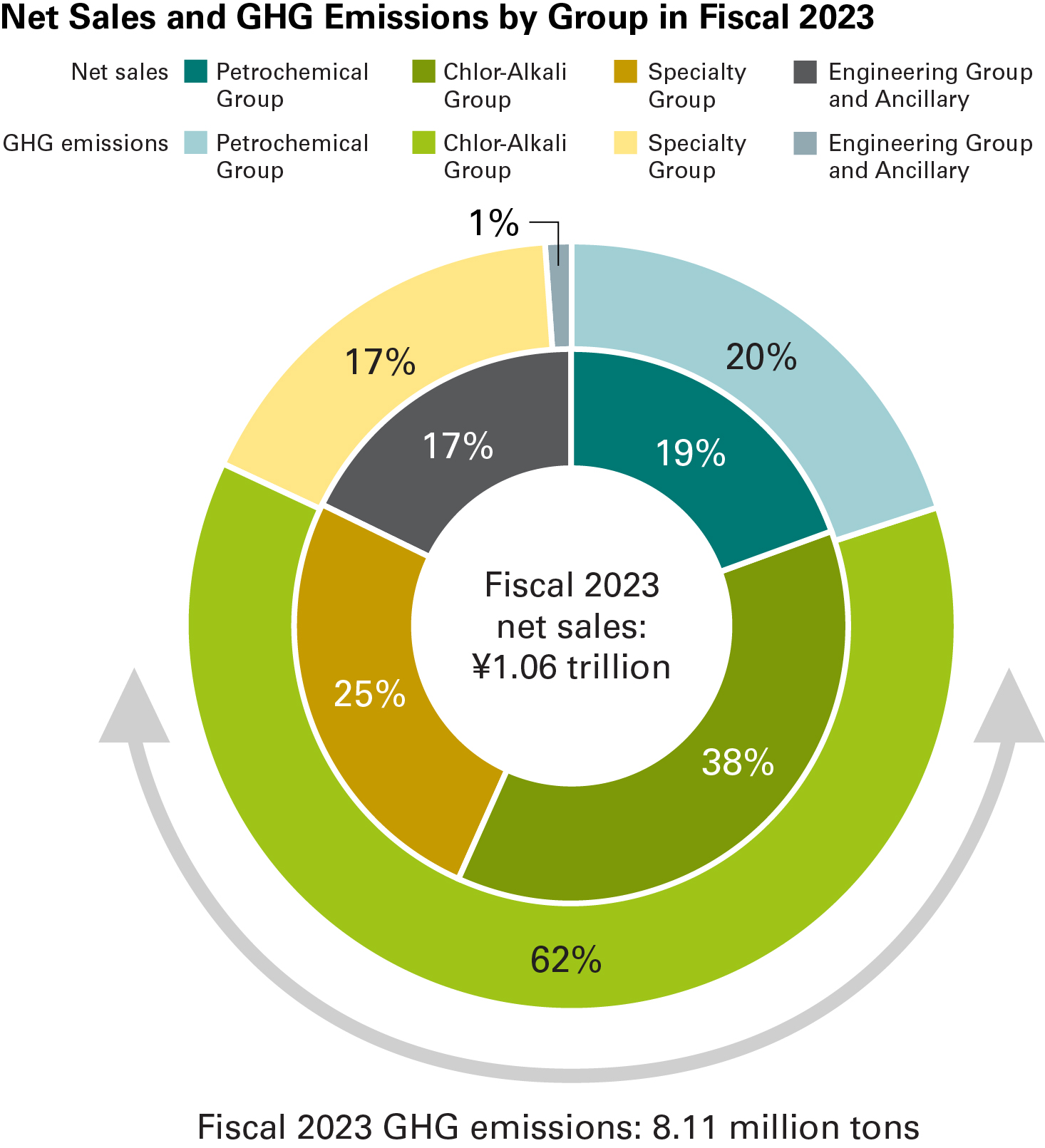

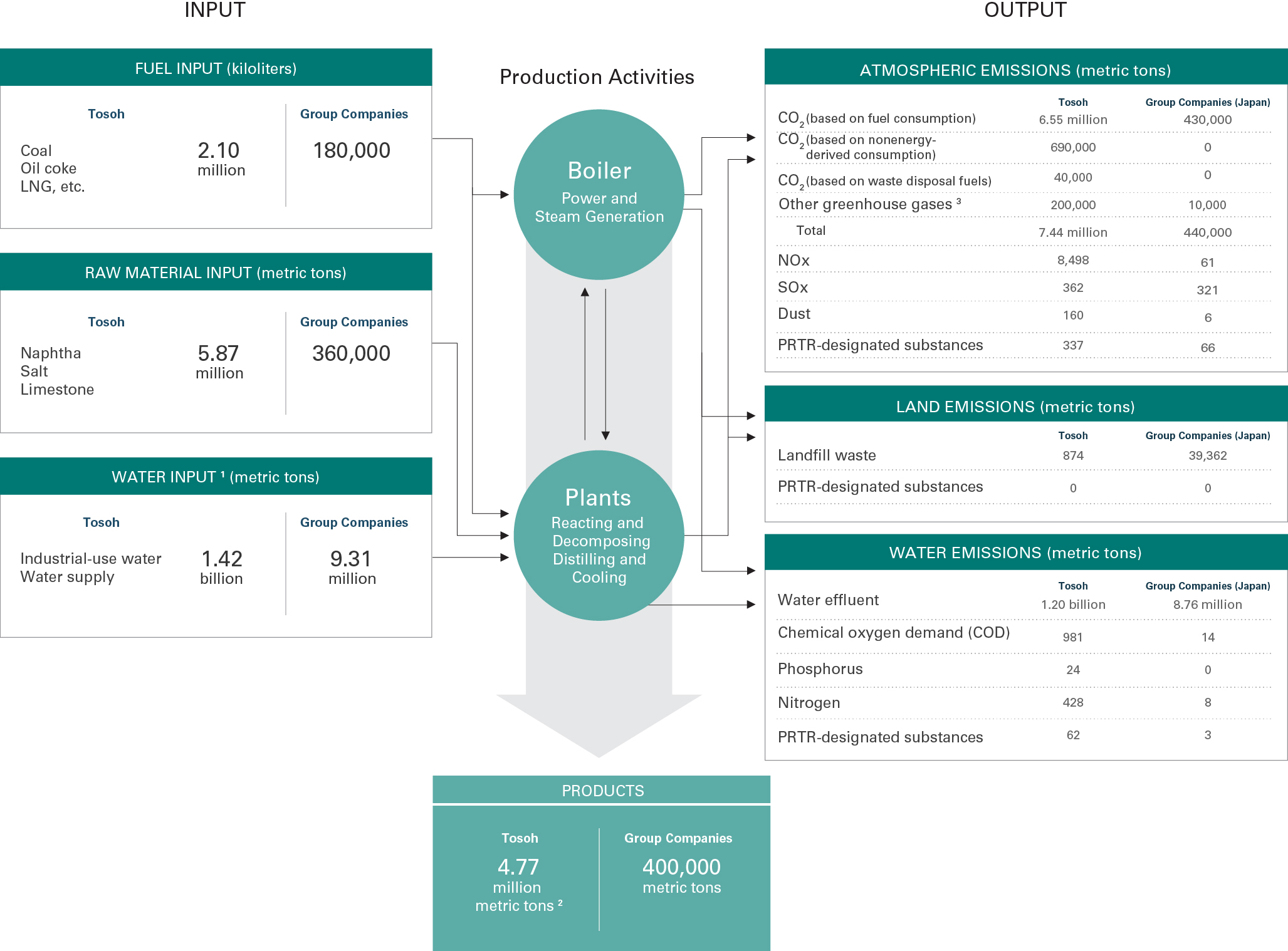

The diagram below details the Tosoh Group’s net sales and GHG emissions by sector for fiscal 2023.

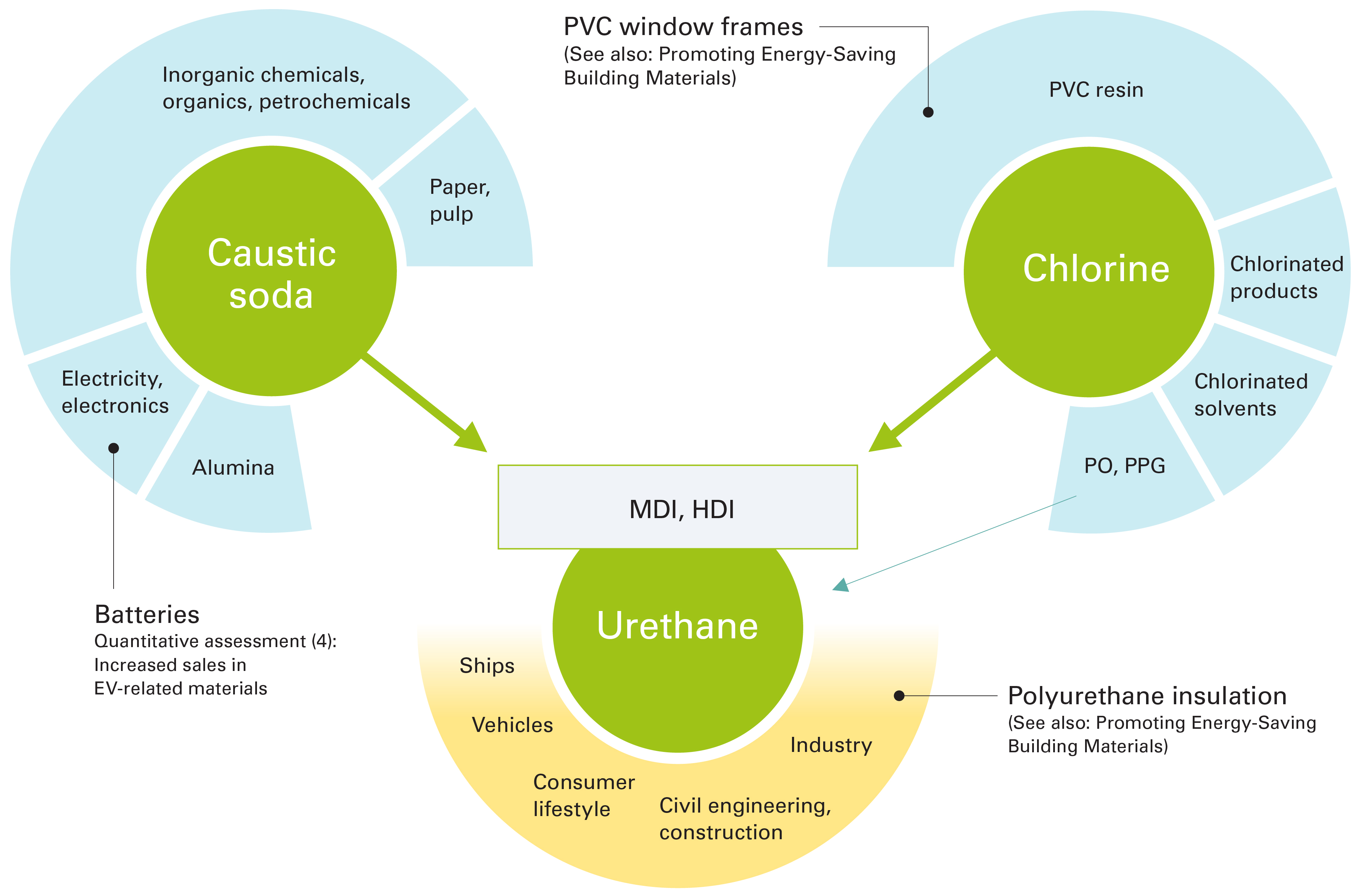

A key issue for the entire Tosoh Group is reducing GHG emissions, thus our analysis focuses on energy-intensive products and technologies. In addition to conducting a company-wide scenario analysis, this year, we also focused on the chlor-alkali sector—from among the four groups of petrochemicals, chlor-alkali, specialty, and engineering/ancillary—which accounts for 62% of the Tosoh Group’s GHG emissions (Scope 1+2).

Assessing the Tosoh Group overall

We must reduce the Tosoh Group’s GHG emissions, which are among the highest in the chemical industry. We have already begun taking concrete steps to address this issue. Key initiatives include shifting to new fuels for our in-house thermal power plants, which account for about 80% of our GHG emissions, and purchasing renewable energy. Potential business opportunities have appeared across various sectors in commodities and specialty products. We intend to focus on future-oriented technology and product development from a broad perspective, viewing our response to climate change as an opportunity.

Assessing the chlor-alkali sector

The chlor-alkali sector comprises the chemicals business (including caustic soda, VCM, PVC, and chlorine derivatives), the urethane business (including MDIs and functional urethane), and the cement business. The business utilizes caustic soda and chlorine produced through saltwater electrolysis. It consumes significant energy from our in-house thermal power plants that use fossil fuels (including coal and petroleum coke), making it a sector with substantial GHG emissions. Thus, the critical issue for this sector—which is also the one most affected by rising energy costs—is the transition to new fuels for our thermal power plants. This is a concern which overlaps across the Tosoh Group. We must reduce our CO₂ emissions from product manufacturing while keeping energy cost increases in check; simultaneously creating a mechanism to pass the value of low-carbon and decarbonized materials through to product prices.

Furthermore, since most of the products in this sector are basic raw materials, they find use in diverse applications – and the impact of climate change poses risks for some applications, and opportunities for others. At this stage, our analysis findings are not biased toward either risk or opportunity. The demand for these products is robust over the long term, and they are poised to be one of the critical pillars of the Tosoh Group’s foundation.

Our Approach to Scenario Analysis

We follow a process for making progress in our scenario analyses. Based on the two scenarios presented in “Assumptions for Scenario Analysis,” we developed a list of possible transition and physical risks on the 2030 to 2050 timeline, together with business opportunities related to climate change. We narrowed this list down through qualitative analysis and identified items for quantitative analysis.

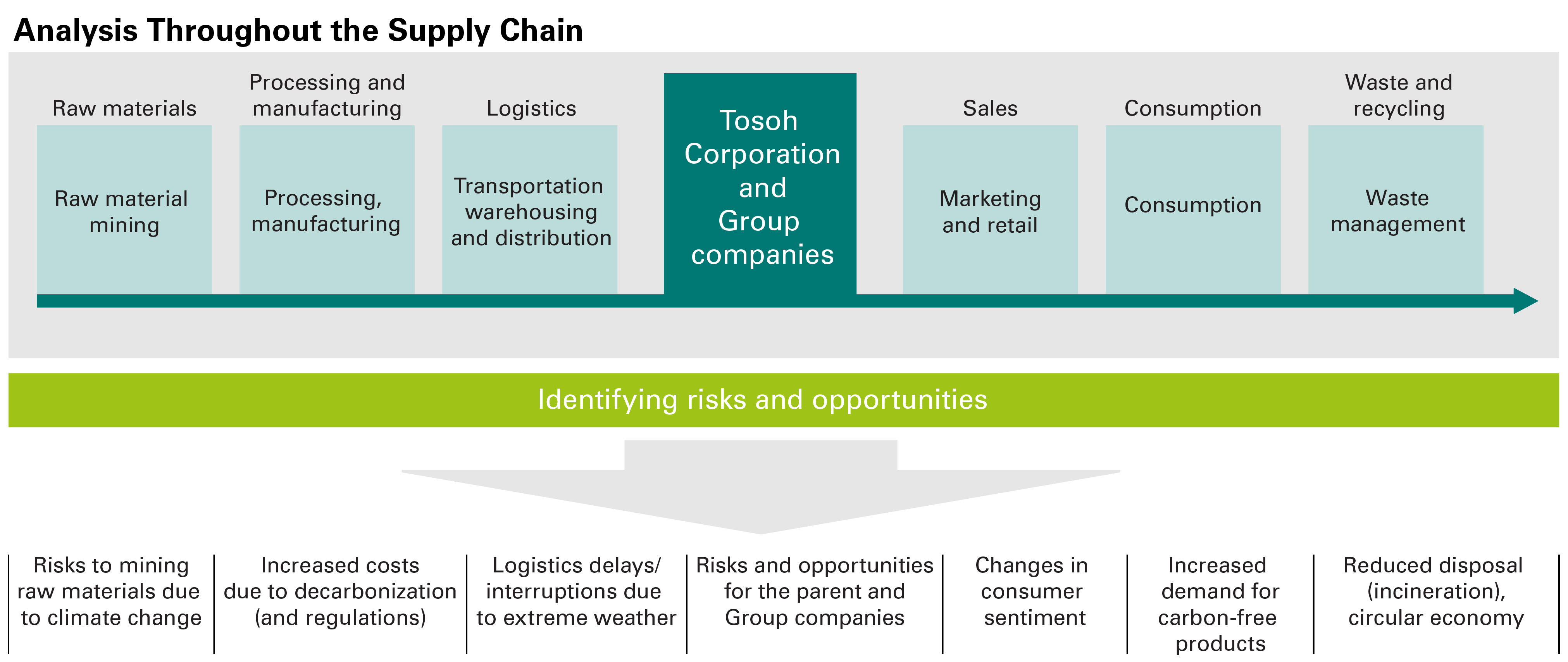

Moreover, we analyzed the impact on the Tosoh Group, considering not only Tosoh and its group companies independently but also the entire supply chain (in terms of raw materials procurement, processing and production, logistics, sales, consumption, and disposal and recycling).

Progress in scenario analysis

|

Summary of each step |

Specific analytical conditions and implementations |

Step 1

Assess the significance of climate-related risks |

Determine climate change-related risks and opportunities for our business (qualitative analysis) |

- Key issues related to climate change

- Market and technological transformation

- Corporate reputation

- Government policy and legislation

- Physical risks |

Step 2

Identify and define scenarios |

Investigate the impact of climate change-related phenomena on our business (scenario analysis) |

- Target businesses: Groupwide + Chlor-Alkali sector

- Target periods: –2030, –2050

- Scenarios: 1.5 ℃, 4 ℃ |

Step 3

Assess the impact on our business |

Create business forecasts and financial impact estimates for each defined scenario (quantitative analysis) |

- Identify the impact on our business

- Formulate strategies reflecting risks and opportunities |

Step 4

Identify potential responses |

Establish measures to address identified risks and opportunities, and indicators to manage these |

- Implement responses

- Cut GHG emissions primarily by converting fuels for in-house thermal power generation facilities

- Develop environmentally friendly products and pass costs on through pricing as appropriate

- Track management indicators

- Targets for reduction by 2030 and carbon neutrality by 2050

- Increase sales of environmentally friendly products |

Step 5

Disclose activities (internally and externally) |

Foster understanding among relevant parties and disclose activities to stakeholders |

- Approve and disseminate disclosure materials through governance reporting and proposals

- Disclose activities via website and annual report |

|

Details for each scenario |

| +1.5 ℃ Scenario |

Scenario with significant CO₂ emission control to limit temperature rise to +1.5 ℃ (WEO: Net Zero Emissions by 2050 Scenario [NZE] *1)

⇒ Treating increased legislation and significant behavioral changes in society and markets as transition risks

|

| +4 ℃ Scenario |

Scenario in which global warming countermeasures make insufficient progress, and the temperature rises to an estimated 4 ℃ above pre-industrial levels by 2100 (IPCC SSP5-8.5 *2)

⇒ Treating extreme weather events and changes in society and ecosystems as physical risks |

- This scenario is put forward in the World Energy Outlook (WEO) 2022, prepared by the International Energy Agency (IEA). It requires achieving global net zero by 2050, in order to limit the temperature increase to +1.5°C by 2100.

- This scenario was presented in the Sixth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC). Based on the framework of Shared Socioeconomic Pathways (SSP), this scenario assumes the competitive regional development of SSP5-8.5, with governmental climate policies eschewed as temperatures rise by 4.4°C (with a likely range of 3.3–5.7°C) by 2100.

Scenario analysis overview

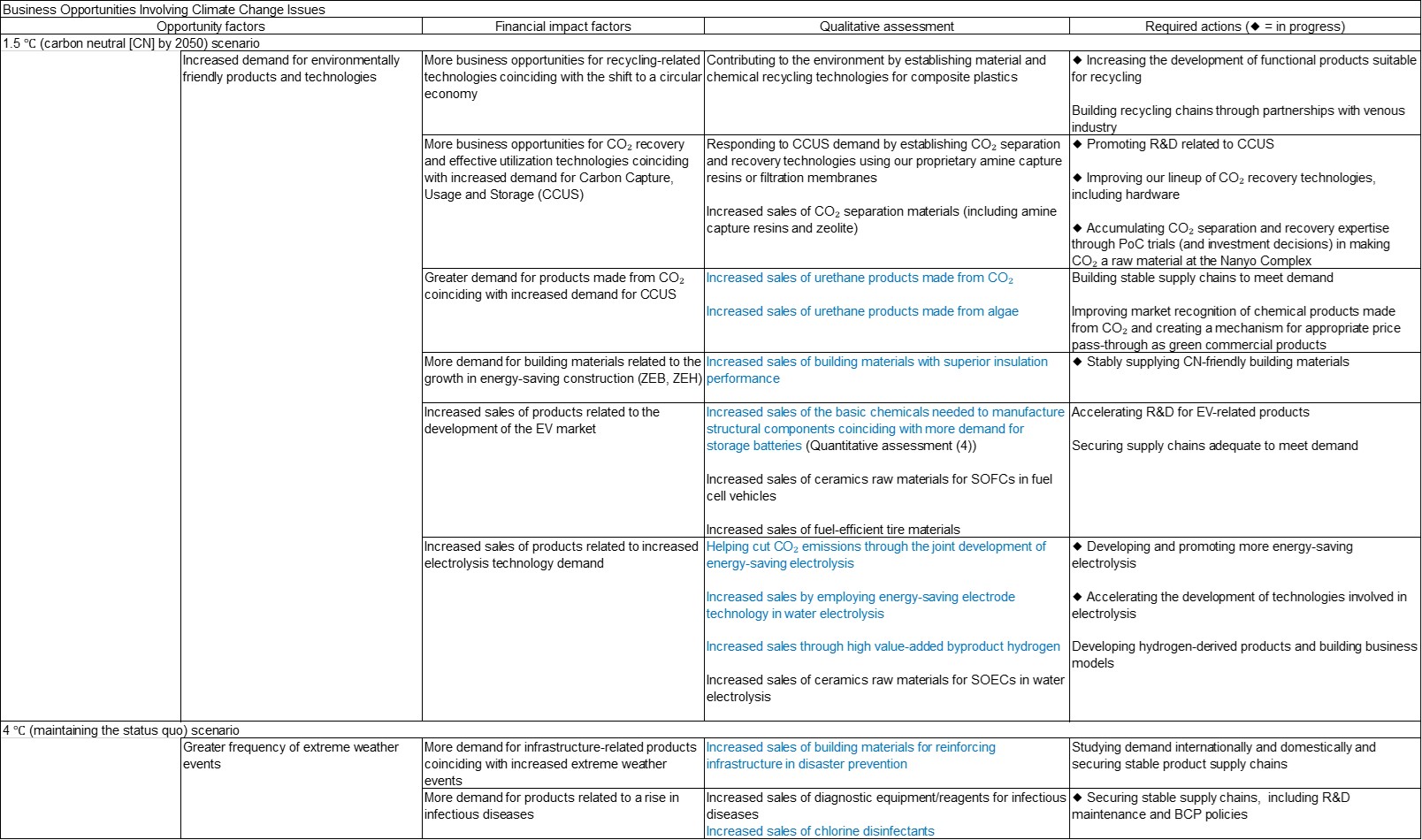

Blue text is related to the chlor-alkali sector.

| Transition/Physical Risks |

| Risk factors |

Financial impact factors |

Qualitative assessment |

Required actions (◆ = in progress) |

| 1.5 ℃ (carbon neutral [CN] by 2050) scenario |

| |

Tighter GHG emission regulations |

Increased fossil fuel-derived costs due to higher carbon pricing |

Increased operating costs related to carbon taxes due to our delayed decarbonization initiatives

Quantitative assessment (1) |

◆ Examining technologies for transitioning from fossil fuels for in-house thermal power plants, responsible for approximately 80% of our GHG emissions

⇒ Diversifying decarbonized fuels

⇒ Investment decisions accounting for future fuel materials and their composition, operational cost impacts, and subsidy availability

⇒ Resolving to invest in biomass power plants (-500,000 tons-CO₂)

◆ Initiatives toward efficiently converting fuels for our in-house thermal power plants through industrial partnerships and implementing CN technology

◆ Studies on creating mechanisms for appropriate price pass-through of CO₂ reduction costs in the GX League's rule formation working group |

| Utilizing our internal carbon price for investment decisions (promoting investment in CO₂ reduction and evaluating business feasibility considering CO₂ increases caused by expanded capacity and other metrics) |

Increased operating costs due to greater renewable energy use in line with client and government demands |

| Transition to decarbonization technologies |

Increased energy costs coinciding with increased usage of renewable energy |

Increased capital investment toward decarbonized power plants (Quantitative assessment (2))

Increased fuel costs for decarbonized power plants |

| Changes in raw material costs |

Increased raw material costs coinciding with rising demand for biofuels |

Increased procurement costs in light of insufficient supply capacity of environmentally friendly biomaterials (including naphtha and benzene) |

Understanding biofuel product demand and diversifying raw material suppliers

◆ Investigating the carbon footprint (CFP) of purchased raw fuels and strategizing to reduce this figure |

| Increased raw fuel costs coinciding with rising carbon pricing |

Pass-through pricing for increased costs associated with initiatives toward decarbonizing raw fuel supplies |

| Changes in consumer behavior |

Decreased sales of products emitting high levels of GHGs coinciding with awareness of low-carbon products and a transition to a circular economy |

Decline in sales of energy-intensive products as well as products in high demand for transition to a circular economy |

◆ Calculating and disclosing CFP by product

Establishing a supply chain and receiving certification for CO₂-free products

◆ Developing materials and systems for a circular economy |

| Decreased sales of gasoline/diesel vehicle products coinciding with the growth of the EV market |

Maintain sales of internal combustion engine-related materials until around 2035 |

Monitoring international regulatory trends, including those relating to synthetic fuels, alongside timely product development and market launch

Developing new applications leveraging the superiority of catalyst technology |

| 4 ℃ (maintaining the status quo) scenario |

| |

More extreme weather events |

Increased losses due to flooding and supply chain disruptions coinciding with greater-than-expected weather damage |

Flooding and storm surge damage at Japanese production sites (Quantitative assessment (3)) |

◆ Implementing business continuity policies in response to environmental changes

⇒ Have implemented damage control measures, primarily for critical electrical equipment, in our tsunami and storm surge flooding policy

⇒ Currently implementing safe shutdown and quick recovery measures for scenarios with flooding up to 1.25 m at Yokkaichi, with its high earthquake and tsunami risk

Reviewing raw material and product inventory capacity and upgrading product depots

◆ Bolstering business continuity plan (BCP) responses throughout the supply chain |

| Reduced operation at downstream plants in the supply chain (including overseas chlor-alkali plants) due to the shutdown of Japanese plants |

Reduced plant operations due to shutdowns at raw fuel and client production sites

Reduced plant operations and increased logistics costs due to vessel docking restrictions and rerouting |

| Rising average temperatures |

Increased operating costs coinciding with rising temperatures |

Decreased work efficiency and extended shutdown periods due to increased risk of heat stroke during regular plant maintenance

Decreased production capacity due to inadequate cooling capacity at plants |

Improving health management systems for such situations

Reviewing plant design standards |

Examples of calculating the financial impact of risk factors

Quantitative assessment (1): Rising carbon pricing

Financial impact factors

The Tosoh Group’s actual GHG emissions (Scope 1 & 2) in fiscal 2023 were 8.11 million tons. We anticipate increasing operating costs commensurate with the carbon tax to be a risk, due to delays in our decarbonization efforts.

Calculation parameters

We calculated fiscal 2023 GHG emissions by summing the GHG emissions of each Tosoh Group company by manufacturing site location, and multiplying these sums by the carbon prices given below. For these we used the NZE Scenario carbon price (¥130 to the US dollar) from the World Energy Outlook 2022.

Assessment results

| (US dollar/ton-CO2) |

2030 |

2050 |

Relevant locations |

| Advanced economies |

140 |

250 |

Japan and the US |

| Emerging markets |

90 |

200 |

China, Indonesia, and Greece |

| Other |

25 |

180 |

Philippines and Malaysia |

Our carbon tax burden assumes no change in GHG emissions from fiscal 2023.

Fiscal 2031: approx. ¥150 billion; fiscal 2051: approx. ¥260 billion

Required actions

- The Tosoh Group aims to cut its overall GHG emissions by 30% compared to fiscal 2019 by 2031, further reducing their impact by achieving carbon neutrality (CN) by 2050.

- We use our internal carbon price (¥6,000/ton-CO₂) to evaluate the profitability of capital investments. Tosoh promotes investment to reduce CO₂ emissions and assess the business feasibility of investments that increase CO₂ emissions due to factors such as capacity expansion, taking into account the increased cost of such investments.

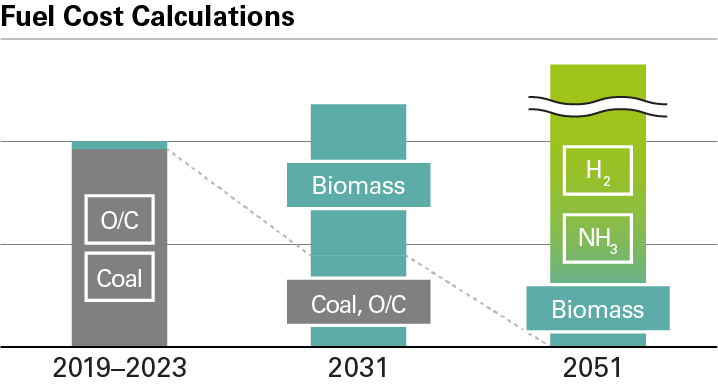

Quantitative assessment (2): Shifting to new fuels for our in-house thermal power plants

Financial impact factors

Since GHG emissions from in-house thermal power plants at our Nanyo and Yokkaichi complexes account for approximately 80% of the Tosoh Group’s emissions, shifting to CO₂-free fuels is imperative. Thus, we anticipate risks from significant increases in capital investment and fuel costs.

Calculation parameters

- We estimate the required capital investment and fuel cost increases based on a fuel composition modeled on reducing GHG emissions by 30% compared to fiscal 2019 by 2031, and achieving CN by 2050.

- For 2031, reducing GHGs through biomass fuel cofiring and effectively using naphtha cracker byproduct gas.

- For 2050, we assume power generation based solely on CO₂-free fuels such as biomass, ammonia, and hydrogen. However, estimating the capital investment and fuel costs is challenging at this stage.

- We use the average fuel cost from fiscal 2019–2023 as the basis for comparison (=1).

- We estimate all fuel costs based on in-house purchase prices, data from the government and related organizations, and other available metrics.

Assessment Results

The cumulative capital investments for shifting to fuels that reduce GHG emissions by 30% by fiscal 2031

Through fiscal 2031: approx. ¥90–120 billion

The fuel cost increase rate for shifting to fuels that reduce GHG emissions by 30% by fiscal 2031

Fiscal 2031: +20% compared to present

Required actions

- We are considering diversifying the fuels for our in-house thermal power generation (various biomass fuels, ammonia, and hydrogen) and purchasing renewable energy to become carbon neutral. See “Initiatives Toward Cutting GHGs” on our CSR website.

- We are looking into approaches for transitioning to fuels that minimize the impact on operating costs while effectively using government subsidies, including subsidies for capital investment and price differential compensation for fuels.

- We promote the efficient decarbonization of our power plants by partnering with companies on fuel procurement, and in other areas, at the Shunan and Yokkaichi industrial complexes. We are discussing with the GX League—an industry-academia-government forum established with the aim of meeting GHG emissions reduction targets—and other groups the creation of a mechanism to pass on the added value of green products manufactured with reduced GHG emissions through our client pricing.

Topics

In July 2022, we decided to invest in a new biomass power plant, including replacing the aging coal-fired pulverized coal boiler in Nanyo with a circulating fluidized bed boiler capable of firing biomass fuels alone.

(Capital investment: approx. ¥40 billion; planned GHG reduction: approx. 500,000 tons; variable cost increase due to this plan: none)

Quantitative assessment (3): Flooding and storm surge damage at production sites

Financial impact factors

In the 4°C scenario (SSP5-8.5), extreme weather events are expected to intensify. Both the Nanyo and Yokkaichi complexes will see flooding from storm surges and other factors, resulting in damage to assets and a risk of lost sales opportunities due to suspended operations.

Calculation parameters

- A private meteorological company calculated the flood depths from storm surges and other sources for 2030 and 2050 at the Nanyo Complex (Shunan City, Yamaguchi Prefecture) and the Yokkaichi Complex (Yokkaichi City, Mie Prefecture), Tosoh’s primary production sites, using Aqueduct* simulations.

- The flood depth calculations assumed a once-a-century probability (meaning a 1% probability of occurrence per year). Quoted figures are the maximums from five simulation models.

- The planned scale (countermeasure targets) of disaster prevention plans for rivers and other bodies of water in large cities is at a probability of once in 100–200 years.

- The estimated financial impact of the flood depths calculated in the above simulations used the following data in the Reference Indicator Tool for the Impact of Natural Disasters on Business (Flood Damage) created by the Disaster Management Consortium of the Cabinet Office.

(1) Business type (= manufacturing), (2) Personnel count (= business size), (3) Topography (= plains)

*A water risk atlas provided by the World Resources Institute

Assessment Results

The maximum amount of one-time property damage due to flooding from storm surges and other sources with a once-a-century probability of occurring as of 2030 and 2050.

Fiscal 2031: approx. ¥5 billion/maximum damage incident; fiscal 2051: approx. ¥9 billion/maximum damage incident

Required actions

- In our tsunami and storm surge flooding policy, we have implemented damage control measures primarily for critical electrical equipment.

- At the Yokkaichi Complex, which is subject to high earthquake and tsunami risk, we are implementing safe shutdown and quick recovery measures assuming flooding up to 1.25m from a predicted tsunami from the anticipated Nankai Trough Earthquake.

- We periodically conduct flooding and storm surge simulations based on projections of future temperature increases, and consider the measures required for stable operations according to the simulation results.

Business opportunities involving climate change issues

Blue text is related to the chlor-alkali sector.

Examples of calculating the financial impact of opportunity factors

Quantitative assessment (4): Increased sales in EV-related materials

Financial impact factors

Storage batteries are considered the most significant technology in the electrification of automobiles (EVs). Cathodes are a component of storage batteries, and highly pure caustic soda is used to produce cathode materials. With the growth of the storage battery market, we anticipate increased use of—and more business from—caustic soda.

Calculation parameters

- The cited data on the expected growth of the storage battery market is from METI’s Storage Battery Industry Strategy (from the Public-Private Sector Council for Storage Battery Industry Strategy).

- The estimate is arrived at by multiplying the current unit sales price of caustic soda for cathode materials by the market growth forecast coefficient.

Assessment Results

The increase in caustic soda sales required for the manufacture of storage battery components in 2030 and 2050:

Fiscal 2031: approx. ¥12 billion; fiscal 2051: approx. ¥20 billion

Required actions

- By gathering information from a wide range of fields, we will quickly identify products and technologies that address climate change issues and invest management resources in these.

- Through close engagement with clients, we will quickly identify the quality, quantity, and timing of products the market demands and reflect this information in our business strategies.

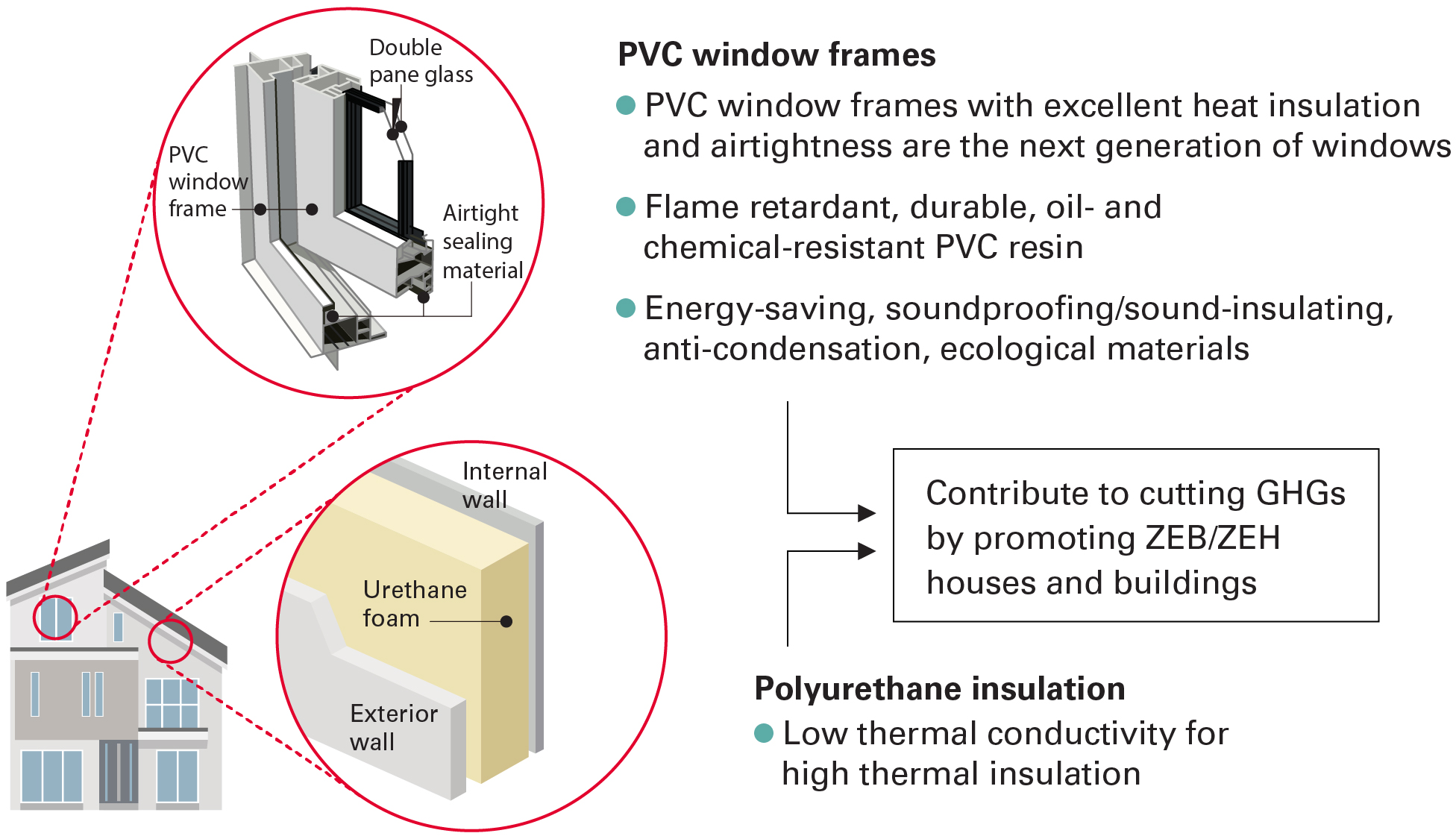

Environmental Contributions from Chlor-Alkali Sector Products

Tosoh’s Chlor-Alkali Group offers basic and process materials for various applications. We have business opportunities in many fields that address climate change mitigation and adaptation.

Cutting GHG through residential building insulation, due to its long-term effects, plays a vital role in the goal of achieving CN by 2050. Materials manufactured by Tosoh—specifically, vinyl chloride resin and urethane resin—also help cut GHGs. See “Solutions for Social Issues” on our CSR website.

Risk Management

Under the jurisdiction of the CSR Committee, each division assesses its potential climate change risks, utilizing information on social trends and discussions of—and consultations with—the Japanese government. The CO₂ Reduction and Effective Use Promotion Committee handles comprehensive risk management related to GHG emissions reduction and effective use. Each division responsible for managing risks associated with business operations identifies the relevant risks, assesses their potential financial impact, and reports to the president. The divisions autonomously handle risk management in each day-to-day business activity under the authority of the director in charge and consult with the Board of Directors as necessary for approval and instruction. Moreover, they use our internal carbon price to formulate capital investment plans, including profitability and environmental impact. We have also adopted climate-related risk as a key CSR issue, and the CSR Committee reports progress to the Board of Directors for PDCA management.

The CO₂ Reduction and Effective Use Promotion Committee promotes strategy planning, issue organization, policy formulation, research and analysis, and progress management related to CO₂ emission reduction and effective use of CO₂ as a raw chemical. The committee has also formulated a roadmap for the challenge of becoming carbon neutral by 2050, by assessing both risks and opportunities.

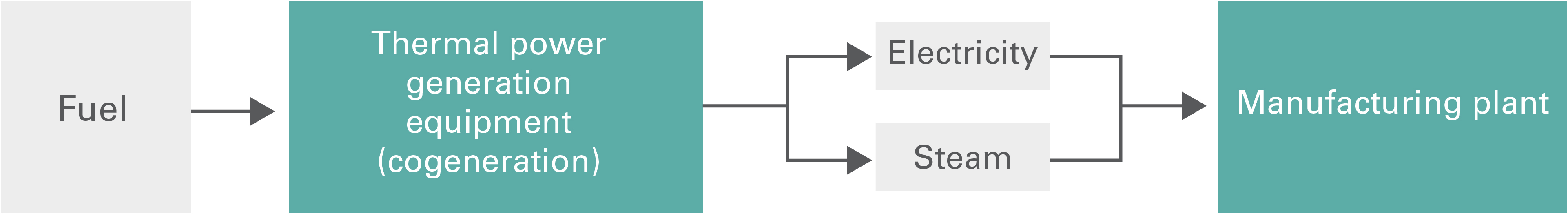

As a risk, Tosoh has high-efficiency cogeneration* in-house thermal power plants to secure the inexpensive and stable power needed for chemical production. If a carbon tax or emissions trading system is introduced in the future, we will incur new costs. We have quantitatively assessed the impact of a carbon tax as part of our strategy (see the “Strategy” section). For instance, if a carbon price of $100/ton-CO₂ (¥130/$) applies to emissions trading to achieve reduction targets, and we purchase emissions credits equivalent to 100,000 tons-CO₂, the cost burden will be approximately ¥1.3 billion.

As a means of capturing opportunities, we have begun assessing the environmental contributions of existing products, and we plan to increase sales through the growing market for products and services that mitigate environmental impact. In R&D, we have designated life science, electronic materials, and environment/energy as priority fields as we work to create products and services that respond to market needs and social issues related to climate change.

*Cogeneration: A system that recovers and uses the heat produced during power generation

Assumed climate-related risks and opportunities

|

Risks |

Opportunities |

| Medium-term (through 2030) |

Long-term (through 2050) |

Medium-term (through 2030) |

Long-term (through 2050) |

| Government policy, laws, and regulations |

Increased costs from carbon prices (carbon taxes and carbon trading) |

Innovation for a low-carbon/decarbonized society

- Environmentally friendly products and services (marketing environmentally friendly products)

- Offices using clean energy

- Technologies for CO₂ separation, recovery, and recycling

Making infrastructure resilient

- Building urban infrastructure (building materials)

- Building IT networks (IT materials)

- Supporting comfortable lives (improving QOL)

- Building business infrastructure (safe & stable supply chains)

|

| Technology |

Introducing cofiring technologies (hydrogen, ammonia, biomass, and waste plastic) |

Introducing renewable energy |

| Markets and reputation |

Raw materials & energy (supply and pricing)

Consumer preferences & stakeholders

|

| Weather |

Extreme weather (wind damage, heavy rains, drought) |

Persistent damage (rising temperatures and sea levels) |

Indicators and targets

GHG emission targets

Climate change is becoming a social issue of great interest worldwide. The need to raise GHG emission reduction targets is at the heart of this issue. In response to the Japanese government’s October 2020 declaration of carbon neutrality by 2050 and reestablishment of GHG emission reduction targets for fiscal 2031, Tosoh reviewed its previous target for fiscal 2026 (non-consolidated BAU* emissions against the fiscal 2014 baseline) and formulated a new GHG emission reduction policy for the entire Tosoh Group in January 2022.

GHG emissions reduction policy

- Cutting GHG Emissions (Scope 1+2) by 30% compared to fiscal 2019 by fiscal 2031

- Tackling becoming carbon neutral by 2050

In March 2023, the Japan Chemical Industry Association (JCIA), of which Tosoh is a member, set the following target for fiscal 2031 to achieve carbon neutrality by 2050:

- 32% reduction (compared to fiscal 2014) by fiscal 2031

Tosoh’s new target aligns with the JCIA’s latest target. As a member company, we will also help achieve industry targets.

*Business As Usual (BAU) emissions = production volume x CO₂ intensity in the reference year

Climate-related indicator categories

| Transition risks |

Government policies and regulations concerning carbon pricing and other issues, progress in introducing renewable energy (shifting to new fuels) and other technological innovations, and markets and reputation related to consumer preferences |

| Physical risks |

Operational shutdowns or logistics delays (in purchasing and shipping) due to extreme weather (including flooding or storm surges)

|

| Opportunities from climate change |

Building business infrastructure to stably supply environmentally friendly products and services, or urban infrastructure-related products and materials |

| Capital allocation |

Plans to invest ¥120 billion in climate change-related investments by fiscal 2031 and ¥60 billion by fiscal 2027 (based on final investment decisions) |

| Internal carbon price |

Tosoh applies an internal carbon price system (¥6,000/t-CO₂) to promote capital investment that helps cut GHG emissions. |

GHG Emissions and Energy Use Results

An independent third party guarantees our GHG emissions.

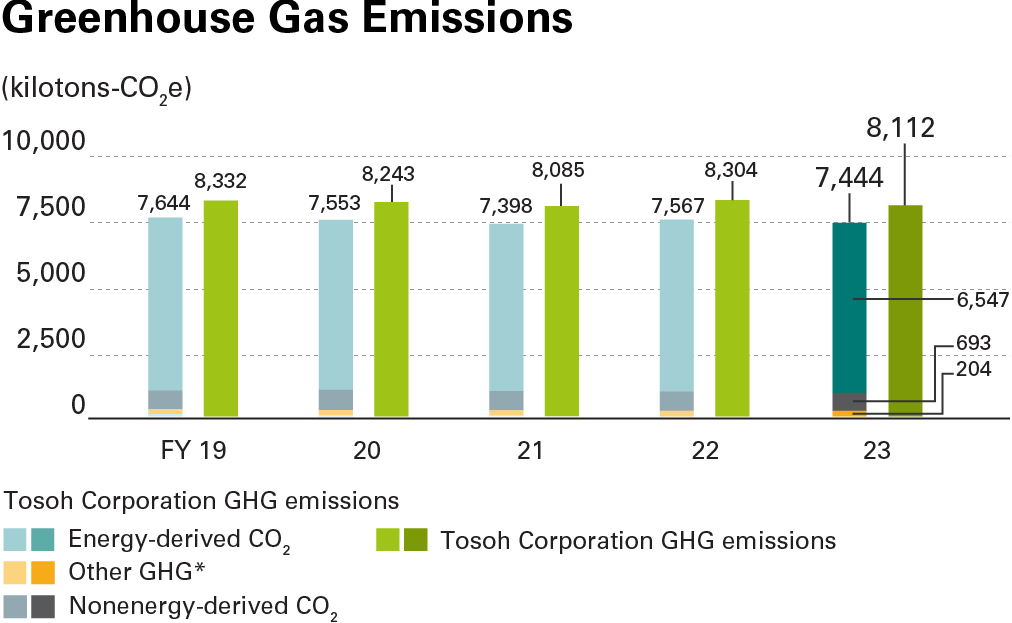

GHG Emissions (Tosoh Group)

The Tosoh Group's GHG emissions (Scope 1+2) in fiscal 2023 totaled 8.112 million tons CO₂e, a decrease of 192,000 tons CO₂e from fiscal 2022.

Emissions levels rose in fiscal 2022, due to increased production amid the market’s recovery from pandemic-related decline. In fiscal 2023, however, a decrease in this figure stemmed from the effects of reduction measures and the impact of market conditions. We are actively promoting capital investment for fuel and energy conservation in order to achieve our target of reducing energy-derived CO₂ emissions, which constitute the majority of our emissions.

All GHG emissions are calculated using our Calculation, Reporting, and Publication Systems for Greenhouse Gas Emissions.

We have expanded these calculations to include the manufacturing and logistics sites of 53 domestic and overseas group companies, using formulas for adjusted greenhouse gas emissions.

“Other GHG” represents the total emissions for N₂O, CH₄, SF₆, and HFC.

Scope-specific GHG Emissions (Tosoh Group)

To understand the greenhouse gas (GHG) emissions across the entire supply chain of the Tosoh Group, emissions are calculated by scope.

GHG emissions by scope (Tosoh Group)

|

Fiscal 2019 |

Fiscal 2020 |

Fiscal 2021 |

Fiscal 2022 |

Fiscal 2023 |

| Scope 1 |

7,797 |

7,727 |

7,588 |

7,787 |

7,645 |

| Scope 2 |

535 |

516 |

496 |

518 |

467 |

| Scope 1 + 2 |

8,332 |

8,243 |

8,085 |

8,304 |

8,112 |

We have expanded these calculations to include the manufacturing and logistics sites of 53 domestic and overseas group companies, using formulas for adjusted greenhouse gas emissions. Additionally, greenhouse gas emissions derived from waste fuel are not included here but are listed separately.

Calculated values for Scope 3 Emissions

|

Category |

Fiscal 2019 |

Fiscal 2020 |

Fiscal 2021 |

Fiscal 2022 |

Fiscal 2023 |

| 1 |

Purchased products and services |

2,321 |

2,787 |

2,623 |

2,940 |

2,657 |

| 2 |

Capital goods |

134 |

193 |

139 |

125 |

155 |

| 3 |

Fuels and energy-related activities not included in Scope 1 + 2 |

1,071 |

1,306 |

1,287 |

1,359 |

1,066 |

| 4 |

Transportation/delivery (upstream) |

473 |

522 |

423 |

446 |

421 |

| 5 |

Waste from business |

17 |

17 |

16 |

19 |

17 |

| 6 |

Business travel |

7 |

16 |

2 |

3 |

10 |

| 7 |

Employee commuting |

9 |

11 |

12 |

14 |

14 |

| 8 |

Leased assets (upstream) |

- |

- |

- |

- |

- |

| 9 |

Transportation/delivery (downstream) |

- |

- |

- |

- |

- |

| 10 |

Sold product processing |

- |

- |

- |

- |

- |

| 11 |

Sold product use |

108 |

148 |

156 |

150 |

73 |

| 12 |

Sold product waste |

1,874 |

2,066 |

1,938 |

1,984 |

1,477 |

| 13 |

Leased assets (downstream) |

- |

- |

- |

- |

- |

| 14 |

Franchses |

- |

- |

- |

- |

- |

| 15 |

Investments |

- |

- |

- |

- |

- |

|

Total |

6,014 |

7,066 |

6,596 |

7,039 |

5,891 |

Scope 1: Direct emissions from fuel combustion and plant operation by Tosoh.

Scope 2: Indirect emissions from electricity and heat supplied by other companies.

Scope 3: Other indirect emissions (emissions from mining and transportation of raw fuel; transportation, use, and disposal of products; and employee commuting and business travel).

Tosoh is promoting the use of energy from both internally and externally generated waste. We are striving to reduce consumption of fossil fuels by effectively utilizing waste oil, waste liquids, general waste plastics, and industrial waste generated through processes such as fuel manufacture. The standard used to collect activity data and calculate emissions is the Act on Promotion of the Measures to Cope with Global Warming (Japan, revised 2005).

Moreover, the emission coefficient is calculated using an adjusted coefficient that takes into account the use of electricity from renewable sources. The adjusted GHG emissions calculation does not include emissions from waste used as energy.

|

Fiscal 2019 |

Fiscal 2020 |

Fiscal 2021 |

Fiscal 2022 |

Fiscal 2023 |

| Waste fuel-derived GHG emissions |

54 |

49 |

50 |

55 |

41 |

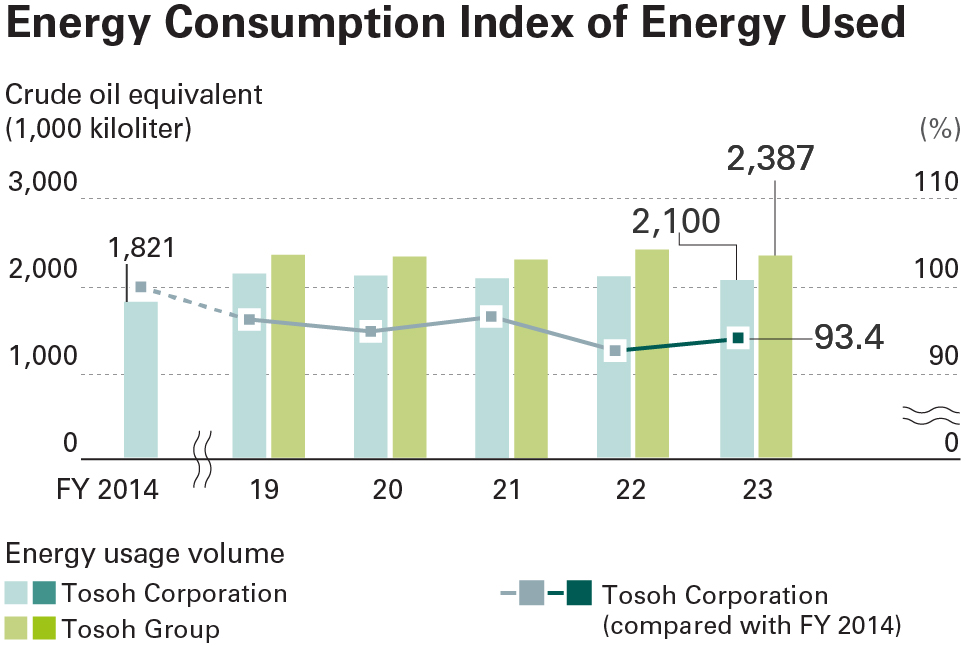

Energy Consumption Index of Energy Used (Tosoh Group)

Tosoh's energy intensity index for fiscal 2023 was 93.4% compared with fiscal 2014. Energy efficiency fell by 0.8 percentage points compared with fiscal 2022, due to lower energy efficiency stemming from decreased production volume and other factors.

Energy consumption (crude oil equivalent of 1,000 kl) is calculated based on the Japan’s Act on the Rational Use of Energy (Energy Conservation Act), and the energy consumption from biomass is also incorporated. The energy intensity index (compared to fiscal 2014) is calculated based on the Energy Conservation Act. When calculating energy consumption specifically for Tosoh Corporation, we deduct the energy sold to other firms.

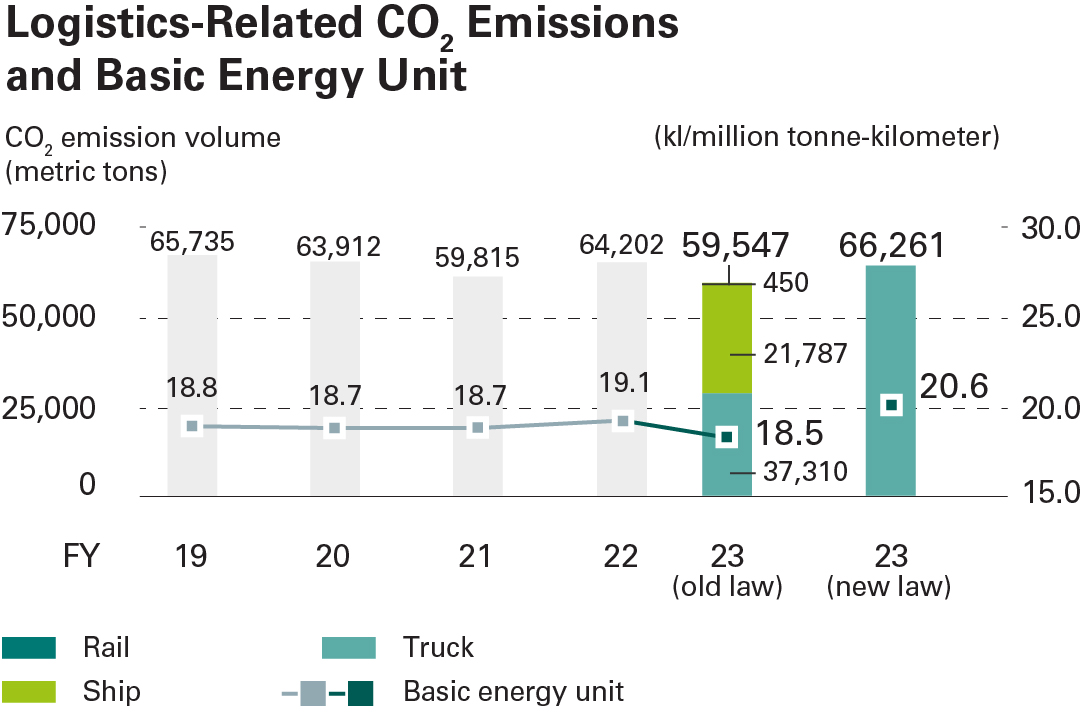

Logistics-Related CO2 Emissions and Basic Energy Unit

In fiscal 2023, Tosoh's logistics CO₂ emissions increased by 3.2% compared with fiscal 2022. The logistics energy intensity*1 was 20.6, a 7.9% regression from fiscal 2022. Factors contributing to this regression include deteriorating truck energy consumption values due to revised expected truckload rates with the improved ton-kilometer formula. Excluding the impact of the revision, the logistics energy intensity was 18.5, an improvement of 3.1% from fiscal 2022, due to improvements in energy consumption for vessels with high ton-kilometer ratios (e.g., improved transportation efficiency through the energy-saving operation of tankers and the use of alternative vessels offering superior fuel efficiency).

To reduce CO₂ emissions, we are continuously promoting energy efficiency through a modal shift in transport that sees us promoting marine and rail transport and improving transportation fuel efficiency. In March 2022, the caustic soda carrier Toyo Maru received the highest rating for domestic vessels under the Ministry of Land, Infrastructure, Transport and Tourism's energy conservation rating system.

Hull improvements (hardware)

- Reduced viscous drag

- Suppressed wave-making drag

- Improved propeller efficiency

Operational support and cooperation (software)

- Operational data management

- Reduced energy loss from slow steaming

- Demonstration project for improving domestic vessel operational efficiency*2

- Logistics energy intensity = crude oil equivalent consumption (kol) / transported ton-kilometer (million tons-kilometer)

- We assess the effect of energy-saving operations by monitoring vessel data before and after sailing, using forecasting information provided by tablet devices equipped with ocean tide and current forecasts.

Tosoh Group Greenhouse Gas Emissions Calculation Method

Scope of aggregation

Tosoh: Nanyo Complex, Yokkaichi Complex, Tokyo Research Center, head office & branch offices

Domestic group companies (34): Hokuetsu Kasei Co., Ltd., Rensol Co., Ltd., Toyo Polymer Co., Ltd., Sankyo Chemical Industry, Inc., Ace Pack Co., Ltd., Tohoku Tosoh Chemical Co., Ltd., Minamikyushu Chemical Industry Co., Ltd., Taiyo Vinyl Corporation1, Plas-Tech Corporation, Taihei Chemicals, Ltd., Asia Industry Co., Ltd., Nippon Miractran Co., Ltd., Tosoh Finechem Corporation, Tosoh Hi-Tec, Inc., Tosoh AIA, Inc., Tosoh Hyuga Corporation, Tosoh Ceramics Co., Ltd., Tosoh Zeolum, Inc., Tosoh Silica Corporation, Tosoh Speciality Materials Corporation, Tosoh Quartz Corporation, Tosoh SGM Corporation, Rin Kagaku Kogyo Co., Ltd., Organo Corporation, Organo Food Tech Co., Ltd., Tosoh Logistics Corporation2, Koun Industry Co., Ltd.2, Keiyo Koun Corporation2, Koun Marine Co., Ltd.2, Yokkaichi Koun Corporation2, Kansai Kaiun Co., Ltd.2, Yamaguchi Koun Corporation2, Toho Unyu Co., Ltd.2, Hyuga Unyu Co., Ltd.2

Overseas Group companies (19): Tosoh (Guangzhou) Chemical Industries, Inc., Philippine Resins Industries, Inc., Tosoh Polyvin Corporation, Mabuhay Vinyl Corporation, P.T. Standard Toyo Polymer, Tosoh (Ruian) Polyurethane Co., Ltd., Tosoh (Shanghai) Polyurethane Co., Ltd., Tosoh Bioscience LLC, Tosoh Bioscience Wisconsin, Inc., Tosoh SMD, Inc., Tosoh SMD Korea, Ltd., Tosoh (Shanghai) Polyurethane Co., Ltd., Tosoh Quartz, Inc., Tosoh Quartz Co., Ltd., Tosoh Quartz Korea Co., Ltd., Tosoh Advanced Materials Sdn. Bhd., Tosoh Hellas Single Member A.I.C., Tosoh Logistics Warehouse Co., Ltd., Oriental Marine Corporation2, 3

- Yokkaichi Plant data is included within that of the Yokkaichi Complex.

- Logistics Group companies

- Included in Tosoh Logistics Corporation

Target of calculation

The calculation includes manufacturing and logistics bases of domestic and overseas group companies, and excludes offices located independently.

Calculation method

In the calculation of GHG emissions for fiscal 2023, in addition to the above expansion of the scope of aggregation and handling of calculation targets, the calculation method is based on adjusted GHG emissions. Therefore, the emission factors for electricity are based on adjusted emission factors and do not include waste fuel-derived GHGs, which are listed separately.

Tosoh Group calculations of greenhouse gas emissions

| Category |

Definitions & calculation formulas |

| Energy consumption |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies. The energy consumption calculation is based upon the Act on the Rational Use of Energy (the “Energy Conservation Act”). It involves multiplying the amount of each fuel used and the amount of power and steam purchased from outside the group (all physical data) for the relevant year by the calorific value of each fuel unit specified by the Energy Conservation Act and the conversion coefficient (1 gigajoule = 0.0258 kL of crude oil equivalent). The calorific value from biofuels is calculated by multiplying the amount used in the relevant year (physical data) by the unit calorific value of each fuel. We used the unit calorific values for wood specified in the Act on Promotion of Global Warming Countermeasures (the “Anti-Global Warming Act”) and obtained those for other fuels separately. |

| CO₂ emissions from energy sources |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies. Based on the Act on the Rational Use of Energy, the total was the sum of the calculated values using the equations below:

- Volume of each fuel used in the relevant fiscal year (physical data) X the unit calorific value of each fuel X the emission factor of each fuel

- Volume of electricity purchased externally X emission factor for electricity

- Amount of steam purchased externally X steam emission factor

The unit calorific value and emission factor specific to each fuel are based on the calculation, reporting, and publication system of the Act Concerning the Promotion of the Measures to Cope with Global Warming. Emission factors for electricity in Japan are based on values for each electric utility for the relevant fiscal year. Emission factors for electricity overseas are the fiscal 2021 values for each country listed in the 2022 edition of Emissions Factors published by the International Energy Agency (IEA). Emission factors for steam overseas is the value from Citation 1.

|

| CO₂ greenhouse gas emissions from non-energy sources and non-CO₂ greenhouse gas emissions |

CO₂ greenhouse gas emissions from non-energy sources and non-CO₂ greenhouse gas emissions |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies. Calculation formulas, calorific values, emission coefficients, and global warming potential are based on the calculation, reporting, and publication systems prescribed in the Anti-Global Warming Act. |

Scope 3

Greenhouse gas emissions |

Calculated using [From activities] x [Emission coefficient] based on the following approach: |

Category 1:

Sold products and services |

Calculations include Tosoh Corporation, Japanese group companies (excluding Organo Corp.), and overseas group companies (excluding Tosoh Bioscience LLC, and Tosoh Bioscience Wisconsin, Inc.).

(1) Companies in the above calculations except the Tosoh Logistics Group companies

[From activities]

The amount of primary raw materials procured by each group company from outside the group (total shown in the Input/Output column of the Tosoh Report; physical data)

[Emission coefficient] Uses values from (Source 1)

(2) Tosoh Logistics Group companies

[From activities] Repair and maintenance costs

[Emission coefficient] Uses values from (Source 2) |

Category 2:

Capital goods |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies.

[From activities]

The asset value of buildings and structures, machinery and equipment, vessels, vehicles, tools, furniture, fixtures, and land purchased or acquired during the given fiscal year (monetary data)

[Emission coefficient]

Uses values from (Source 2) |

Category 3:

Fuels and energy-related activities not included in Scope 1+2 |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies.

[From activities]

Fuel used by type for Tosoh Corporation and group companies, power and steam purchased from outside the group (all physical data)

[Emission coefficient]

Uses (Source 1) for fuels and (Source 2) for the emission coefficient of purchased power and when purchasing steam fuels |

Category 4:

Transportation/delivery (upstream) |

The scope of aggregation encompasses Tosoh Corporation, Japanese group companies (excluding Organo Corporation and logistics group companies), and overseas group companies (excluding Tosoh Bioscience LLC, Tosoh Bioscience Wisconsin, Inc., and logistics group companies).

1) Transportation of raw materials

Activity level: Volumes (physical data) of major raw materials used by Tosoh Corporation and Group companies (total volumes are shown in the Input/Output section on the website (Environmental Protection)), and transportation distances from the suppliers of each raw material to Tosoh Corporation and Group companies.

Assumed standard transportation distances for domestic procurement: 500 km for land, and 1,000 km for marine

For international marine transportation, values from Citation 1 are used for transportation distances

Emission factors: Citation 1

2) Product delivery

1. Domestic transportation

Tosoh Corporation: Reported values under the Act on the Rational Use of Energy and the Known Shipper/Regulated Agent system

Group companies

Activity level: Product shipment volume (quantity data) and transportation distance for each Group company. Assumes uniform standard transportation distances of 500 km for land and 1,000 km for marine.

Emission factors: Citation 1

2. International Transportation

Activity level: Product shipment volume (physical data) and transportation distance for Tosoh Corporation and Group companies. Transportation distances are based on the values in Citation 1.

Emission factors: Citation 1

|

Category 5:

Waste from business |

Calculations include Tosoh Corporation and Japanese group companies.

[From activities]

The amount of industrial waste generated by Tosoh Corporation and Japanese group companies and incinerated, landfilled, or recycled outside the group (physical data)

[Emission coefficient]

Uses values from (Source 2) |

Category 6:

Business trips |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies.

[From activities]

Tosoh Corporation’s business trip expenses for the given fiscal year (categorized as domestic travel expenses [rail], Japanese taxi fares, and international travel expenses [international flights]) (financial data)

Group companies use representative values calculated based on the personnel count ratio to Tosoh Corporation

[Emission coefficient]

Uses values from (Source 2) |

Category 7:

Employee commuting |

Calculations include Tosoh Corporation, Japanese group companies, and overseas group companies.

[From activities]

Tosoh Corporation’s commuting expenses for the given fiscal year (categorized as commuter pass expenses [rail] and gasoline expenses [personal vehicles]) (financial data)

Group companies use representative values calculated based on the personnel count ratio to Tosoh Corporation

[Emission coefficient]

Uses values from (Source 2) for rail and from (Source 1) for personal vehicles |

Category 8:

Leased assets (upstream) |

The assets in question are trivial and therefore excluded from calculations as their associated emissions impact is negligible. |

Category 9:

Transportation/delivery (downstream) |

Emissions from product transportation are calculated in Category 4.

Downstream emissions other than those generated during product transportation are excluded from the calculation because it is difficult to reasonably calculate emissions from diverse, complex transportation and delivery modes. |

Category 10:

Sold product processing |

The Tosoh Group’s products are mainly materials and components that require various forms of processing before being utilized by end users. Therefore, reasonably estimating the type or scale of processing methods is challenging. As a result, we excluded these metrics from the calculations based on the WBCSD’s Guidance for Accounting and Reporting Corporate GHG Emissions in the Chemical Sector Value Chain. |

Category 11:

Sold product use |

Calculations include Tosoh Corporation.

Assumes that butane fractions and other products are used as fuel

[From activities]

Sales volume of recovered residual oil and other products (physical data)

[Emission coefficient]

The value set in the Act on Promotion of Global Warming Countermeasures |

Category 12:

Sold product waste |

Calculations include Tosoh Corporation, Japanese group companies (excluding Organo Corp. and Tosoh Logistics Group companies), and overseas group companies (excluding Tosoh Bioscience LLC; Tosoh Bioscience Wisconsin, Inc.; and Tosoh Logistics Group companies).

Assumes that all products produced by the group in the given fiscal year became waste, based on the estimated form of the final products in which the products of Tosoh Corporation and its group companies are used as raw materials. Based on the WBCSD’s Guidance on Accounting and Reporting of Corporate GHG Emissions in the Chemical Sector Value Chain, we basically used the default coefficients of 80% landfill and 20% incineration, of which cinders, waste acids, waste alkalis, scrap metal, glass ceramic waste, mineral dust, debris, soot, and dust were landfilled 100%.

[From activities]

Production volume (excluding anything consumed within the group; physical data)

[Emission coefficient]

Disposal methods (including landfill and incineration): Uses values from (Source 1)

Waste transportation: Uses values from (Source 2) |

Category 13:

Leased assets (downstream) |

The assets in question are trivial and therefore excluded from calculations as their associated emissions impact is negligible. |

Category 14:

Franchises |

No emissions since the group conducts no franchising. |

Category 15:

Investments |

Tosoh Corporation’s holdings in all non-group companies are intended to help develop and maintain business relationships. They are limited to important clients and suppliers. The product of Tosoh Corporation’s holdings multiplied by the GHG emissions of each company is small and therefore excluded from the calculation, as the impact on the Tosoh Group is negligible. |

Emission coefficient source databases

| Source 1 |

The IDEA LCI database (from the National Institute of Advanced Industrial Science and Technology [AIST] and the Sustainable Management Promotion Organization [SuMPO])

Ver. 2.2 up to and including fiscal 2019, ver 2.3 for fiscal 2020–2022, and ver 3.3 for fiscal 2023 |

| Source 2 |

Emission Unit Value Database for Accounting of Greenhouse Gas Emissions by Organizations Throughout the Supply Chain (from the Ministry of the Environment and the Ministry of Economy, Trade and Industry)

Ver. 2.6 up to and including fiscal 2019, ver 3.0 for fiscal 2020, ver 3.1 for fiscal 2021, ver 3.2 for fiscal 2022, and ver 3.3 for fiscal 2023 |

Initiatives Toward Cutting GHGs

In fiscal 2023, Tosoh implemented many initiatives toward cutting GHGs, including effectively using CO₂ in production. This section showcases those efforts, as well as our partnerships with local industrial communities, and our participation in broader environmental activities.

Shifting to new fuels for our in-house thermal power plants at the Nanyo Complex

Manufacturing chemicals requires energy and significant volumes of steam. Tosoh effectively uses the steam generated by its thermal power plants. Despite being subcritical boilers, the steam output and overall efficiency of these plants are higher than those of ultra-supercritical steam generators.* Thus, Tosoh’s cogeneration in-house thermal power plants ensure effective energy utilization and stable plant operations. We are also investigating ways to reduce emissions further, including increasing the ratio of biomass fuels and waste plastics in the cofiring process.

*Power generation efficiency: Subcritical: 38% or less, supercritical: 38%–40%, and ultra-supercritical: 41%–43%. Steam turbine power generation has higher efficiency due to the increased temperatures and pressure from steam.

Building a new biomass power plant

Tosoh decided to build a new power plant that uses primarily biomass fuel at its Nanyo Complex in Shunan, Yamaguchi.

The existing thermal power plant at our Nanyo Complex uses mainly coal, however the new plant will use waste fuels such as construction waste and RPF* alongside wood-based fuels. While effectively using a variety of waste materials as fuel, it will also reduce greenhouse gas emissions. In the future we aim to burn biomass exclusively, thereby reducing CO₂ emissions by approximately 500,000 tons annually.

This facility is scheduled to begin generating electricity in April 2026, promising a significant contribution to the Tosoh Group’s greenhouse gas emissions reduction target. The Tosoh Group continues to promote initiatives toward the challenge of carbon neutrality by 2050, advancing our use of low-carbon and carbon-free energy.

*An abbreviation for refuse-derived paper and plastic-densified fuel, a solid fuel made from waste paper and plastic.

Biomass power plant fuels

Actively using biomass fuels in production

We are working to reduce energy-derived CO₂ emissions by using biomass fuel as a substitute for coal in our in-house thermal power plants at the Nanyo Complex. In fiscal 2023, we used approximately 30,000 tons of biomass fuel, cutting about 40,000 tons1 of CO₂ emissions. In January 2021, Tosoh signed an agreement with Izumi Sangyo Co., Ltd. and Yamaguchi Prefecture’s Shunan City, for the use of wood pruned from trees at public facilities in Shunan City as fuel for private thermal power plants at the Nanyo Complex. At the Shunan Biomass Center, Izumi Sangyo produces woody biomass fuel chips from trees pruned at public facilities in Shunan City. Tosoh cofires these chips with coal at our in-house thermal power plants, thereby reducing greenhouse gas (GHG) emissions.

We also utilize biomass fuel at some of our overseas group companies, resulting in a reduction of approximately 31,000 tons2 of CO₂ emissions in fiscal 2023.

1Calculated using the calorific values of wood and fuel coal and the emission coefficient of fuel coal as stipulated in the Act on Promotion of Global Warming Countermeasures (the “Anti-Global Warming Act”).

2Calculated using the calorific values of wood and crude oil and the emission coefficient for fuel coal as stipulated in the Anti-Global Warming Act.

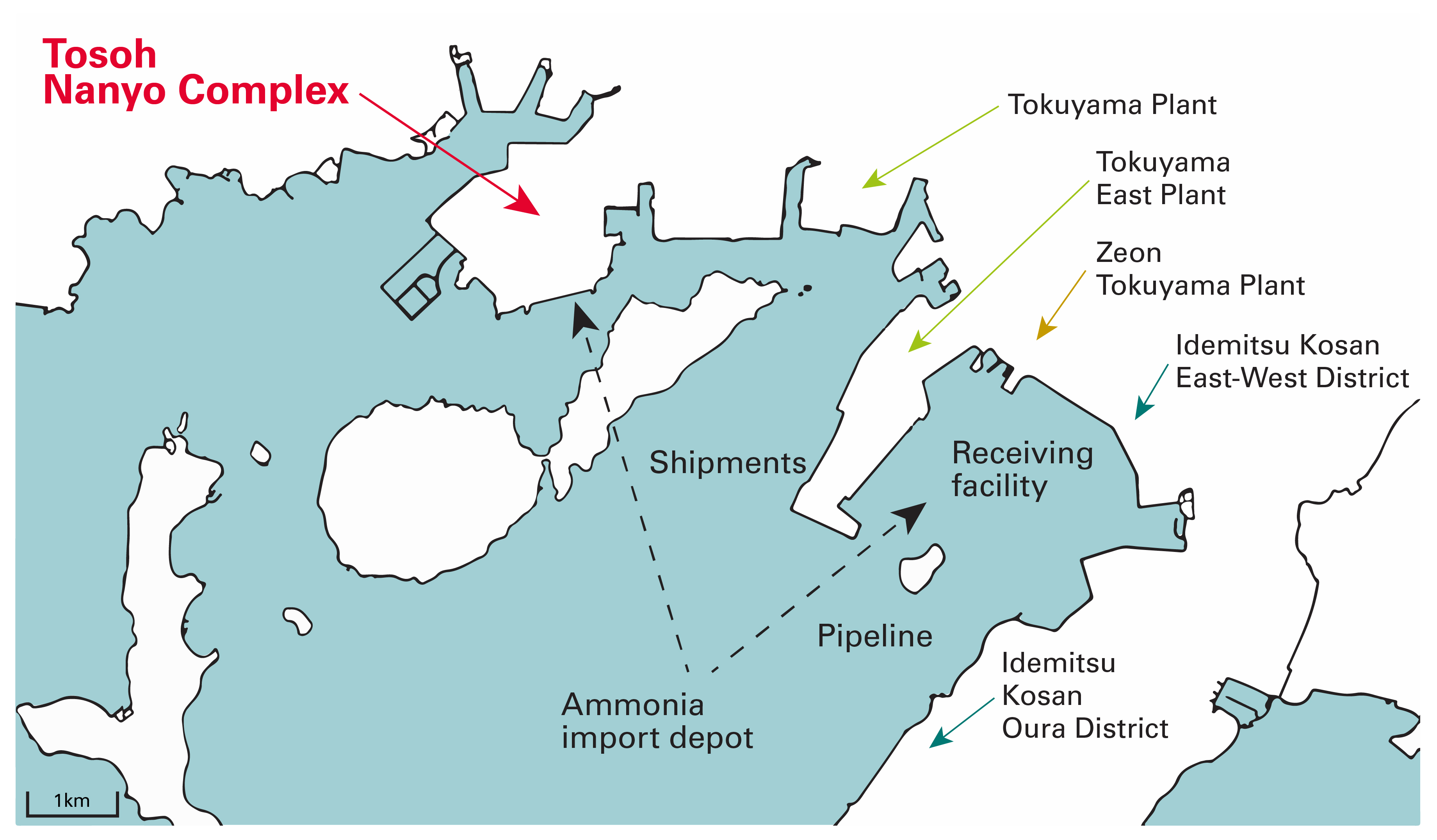

Project for fundamental research toward building an ammonia supply center at the Shunan Industrial Complex

Tosoh, along with three other companies from the Shunan Industrial Complex, was chosen by the Ministry of Economy, Trade and Industry and the Agency for Natural Resources and Energy to receive subsidies to promote non-fossil fuel-based energy as part of the Support Project for Establishment of Hydrogen and Fuel Ammonia Supply Center at Industrial Complex.

The project aims to establish a carbon-free ammonia supply system with an annual capacity of over one million tons by 2030, and includes an ammonia-firing proof-of-concept trial in an operational facility.

In partnership with Shunan City and the Society of Chemical Engineers, Japan (SCEJ), we aim to achieve a carbon-neutral industrial complex by 2050.

Ammonia fuel supply and demand

Separating, recovering, and effectively utilizing CO₂

CO₂ recovery amine

As the trend toward decarbonization gains momentum, demand for CO₂ capture systems is seen increasing. Among these, chemical absorption systems in particular are suitable for recovering CO₂ from fossil fuel boiler exhaust gases, but there is the issue of their durability against NOx in combustion exhaust gases.

Tosoh has developed a high-performance CO₂ recovery amine with superior NOx tolerance that can be used to recover CO₂ from combustion exhaust gases when fossil fuels are employed. The company’s CO₂ recovery amine is forecast to be applied to a vast range of combustion exhaust gases and its high NOx resistance and its excellent energy-saving performance should make possible stable use over the long term.

Furthermore, for practical use, Tosoh introduced a CO₂ recovery demonstration test facility at the Nanyo Complex in 2022, and is working toward optimization, including the system itself.

CO₂ Recovery PoC Trial Facility

As a first step in the practical application of this technology, we decided to install a CO₂ recovery and raw material conversion facility at the Nanyo Complex. The plan is to recover carbon dioxide (CO₂) from facilities that produce naphtha-derived carbon monoxide (CO) and use this CO₂ as a raw material for isocyanate products, one of our flagship products.* Operations are scheduled to start around autumn 2024.

The new facility will recover approximately 40,000 tons of CO₂ per year from firing emissions and effectively use it as a raw material for CO production. The switch from naphtha to CO₂ will lower the carbon content of our isocyanate products.

We will eventually achieve both CO₂ reductions and effective CO₂ utilization through commercial-scale facilities operations, while further improving performance and promoting external sales of CO₂-capture amine-based solutions.

We will continue working toward a carbon-neutral society by embracing innovation, while leveraging our technological expertise and the experience we have amassed over the years.

*Polyurethane made from MDI and other materials

Isocyanate raw material production facility (CO plant)

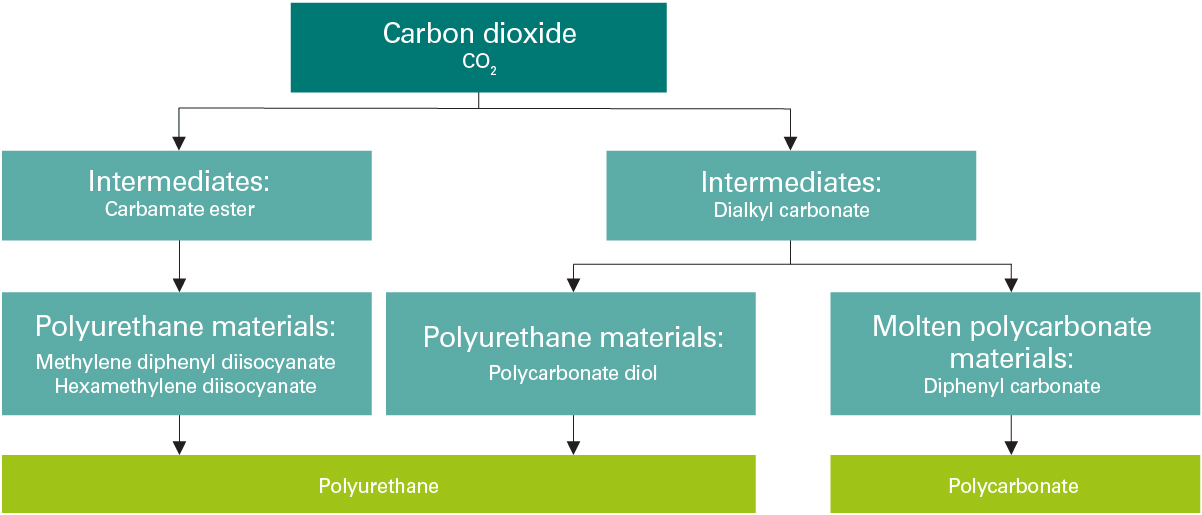

Producing functional chemicals made from CO₂

Tosoh took the lead in a joint research partnership with other companies, universities, and national laboratories. The New Energy and Industrial Technology Development Organization (NEDO) selected this collaboration for the Green Innovation Fund Project.

With a focus on developing manufacturing technology for functional plastic materials using CO₂ as raw material, the project aims both to reduce CO₂ emissions in the manufacturing process of polycarbonate and polyurethane by 2030, and to realize a technology that can use CO₂ as a raw material. The ultimate goal is to improve plastic functionality and achieve production costs equivalent to existing products through a pilot trial.

We believe that our efforts to reduce GHG emissions will lead to medium- and long-term business growth. We will work toward realizing a sustainable society by developing technologies for effectively using CO₂.

Business Vision

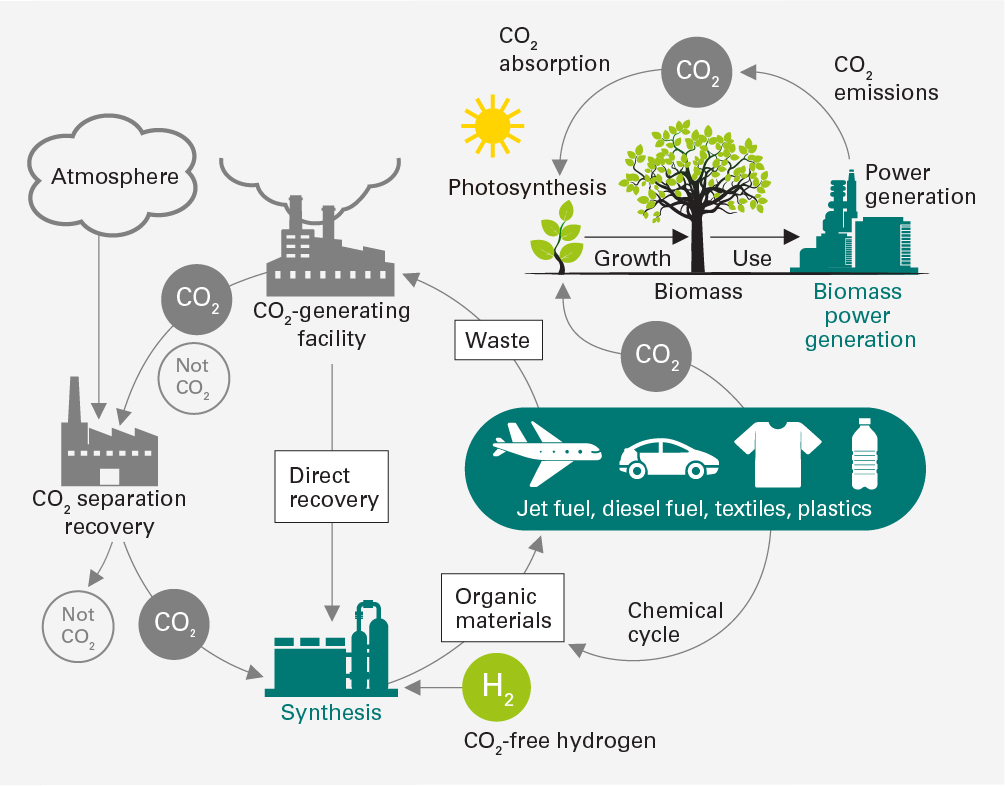

Resource recycling (carbon recycling)

Addressing climate change requires accelerating the transition to a circular economy, and boldly promoting a sustainable and resilient society while transitioning to a decarbonized economy.

In the drive to become carbon neutral by 2050, CO₂ separation, recovery, and effective use (including using it as a raw material for chemicals) and material resource recycling (including recycling plastic materials and chemicals) promise to be critical technologies in cutting GHG emissions and becoming carbon negative.

In addition to the chemical absorption provided by CO₂ capture amines, Tosoh is working to develop an efficient CO₂ separation and recovery process using CO₂ filtration membranes. We also promote technologies to effectively use carbon, including direct CO₂ recovery from combustion exhaust gas, DAC*, as we develop carbon recycling technologies.

Moreover, we are actively developing process technologies for plastic resource recycling through joint research with national research institutes and fellow companies, helping realize a circular economy.

*An abbreviation for Direct Air Capture, a technology for capturing extremely low concentrations of CO₂ in the atmosphere.

Introducing renewable energy

Tosoh Corporation, together with our domestic and overseas group companies, actively promotes the introduction of renewable energy sources, including solar power generation; hydroelectric power generation; and custom power contracts.

Launching PPA* operations at the Tosoh Ceramics Toyama plant

Tosoh Group company Tosoh Ceramics and Nihonkaigas, a Nihonkaigas Kizuna Holdings Group company, signed a third-party ownership agreement for solar power systems (under a PPA model) and launched operations in Toyama City.

Tosoh Ceramics uses the power generated by the solar system in its Toyama plant, contributing to local production and consumption of renewable energy. With additional solar power systems planned for the future, we should be able to gradually meet our projected CO₂ reduction targets for 2030 and 2050. Nihonkaigas owns the solar power systems and supplies the energy they generate.

Introducing and popularizing renewable energy moves us toward addressing climate change and realizing a sustainable society.

*A form of agreement in which the PPA operator, which owns and manages the solar power system, installs the system on a site, roof, or other space provided by the power consumer and supplies the power the system generates to the consumer.

Solar power system

Using hydroelectric power at MVC

Tosoh Group’s Mabuhay Vinyl Corporation (MVC; located in Makati, Philippines) decided to increase the production capacity of its electrolysis facility and that of chlorine derivatives hydrochloric acid and liquid chlorine. As part of this plan, the company will reduce its carbon dioxide emissions by cutting steam and power consumption and further improving its energy use efficiency (i.e., increasing the use of renewable energy) before the planned capacity increase.

Demand for caustic soda is growing in many industries in the Philippines, particularly from the food sector where it is used for cleaning. This demand promises steady growth into the future. Chlorine demand is also growing, for disinfecting the water and sewage systems which are focal points of the country’s developing infrastructure; and for use as bleaching agents. Against this backdrop, MVC will increase the production capacity of its electrolysis facilities and establish a stable supply chain to meet the country’s growing demand for caustic soda and chlorine derivatives. However, electrolysis facilities are energy-intensive, which raises concerns about increased GHG emissions. MVC strives to reduce GHG emissions by using renewable energy from hydroelectric power plants, which make use of the area’s abundant water resources.

The Tosoh Group will keep working to bolster earnings and reduce GHG emissions by leveraging the robust and expanding demand in the Asian region.

Capital investment in energy conservation

One of the basic policies of our new medium-term management plan is to make a group-wide effort to reduce and effectively utilize CO₂ emissions, since Tosoh sees energy conservation as a social responsibility that requires ongoing investment.

- Upgrading caustic soda electrolysis to save energy (Nanyo and Yokkaichi complexes)

- Installing advanced control systems for ethylene plants (Yokkaichi Complex)

- Installing gas turbines and improving efficiency in naphtha cracking furnaces (Yokkaichi Complex)

- Installing state-of-the-art turbines and rotors in in-house thermal power plants (Nanyo Complex)

- Installing optimized load balancing systems in power plants (Nanyo Complex)

- Making ongoing capital investment to increase the ratio of biomass fuel cofiring (Nanyo Complex)

We will keep accelerating our reduction of energy-derived CO₂ emissions by promoting energy conservation through equipment upgrades at our energy-intensive plants.

Gas turbine

Effectively using cement plant waste

The Tosoh Nanyo Complex’s cement plant effectively utilizes both internal and external waste to produce cement and thermal energy. We accept and process approximately 16,000 tons of plastic waste, automobile shredder residues (ASR), and shredder residues (SR) of scrap home appliances as fuel for thermal energy, reducing the CO₂ generated from fossil fuels by approximately 42,000 tons (for fiscal 2023).

Cement plant

Helping reduce CO₂ by licensing energy-saving technologies

Caustic soda electrolysis

Caustic soda is produced by electrolyzing raw materials using ion-exchange membranes (IM).

As Japan’s largest producer using IM-based sodium chloride electrolysis, Tosoh jointly developed an energy-saving electrolyzer in 1995. We have been continually improving this technology ever since, and license it to companies in Japan and abroad thus helping them conserve energy.

Licensees span enterprises in Japan and 35 other countries, for caustic soda production of approximately 21 million tons with reduced CO₂ emissions. In fiscal 2023, CO₂ reductions facilitated by these licenses (solely from caustic soda production transitioned from mercury and diaphragm-based processes) rose to an estimated 590,000 tons (for caustic soda production of approximately 2 million tons).*

*Estimated based on the energy saved from shifting from the mercury and diaphragm processes to Tosoh’s IM-based sodium chloride electrolysis technology for the expected production of licensees. The CO₂ emission coefficients for power by country are those in the 2022 edition of the IEA CO₂ Emissions Factors.

New caustic soda electrolyzer

VCM heat recovery device

Vinyl chloride monomer (VCM), a raw material for PVC resin, is produced through the thermal decomposition of ethylene dichloride. The decomposition furnaces that perform this process generate substantial amounts of heat. Tosoh recovers this heat and reuses it to heat the furnaces, reducing the total amount of fuel required.

We have also licensed this technology to companies in three other countries, achieving a CO₂ reduction of approximately 36,000 tons.*

*Estimated from the energy recovered before and after installing this technology in the licensee production facilities.

Pursuing energy conservation in logistics

Launching caustic soda carrier, the Toyo Maru

In July 2022, we completed construction of our liquid caustic soda carrier, the Toyo Maru.

It is the first coastal vessel equipped with an energy-saving add-on Neighbor Duct. Installed in front of the propeller, this energy-saving add-on generates thrust using the force of flow coming off the hull. The propeller has a vertical and elliptical shape along the hull to utilize greater flow for propulsion. It promises an efficiency improvement of 3.5% compared to ships without the Neighbor Duct system.

Toyo Maru and Neighbor Duct

Considering joint logistics initiatives

In June 2023, Tosoh, Mitsubishi Chemical Group, Mitsui Chemicals, and Toray led the establishment of the Chemical Working Group, part of METI and MLIT’s Realization of the Physical Internet conference1. Forty-four companies and one university have joined the group. It will work toward creating a framework for sustainable logistics that balances productivity and safety with reduced CO₂ emissions, through measures that include reforming commercial practices in logistics; standardization; and formulating, informing stakeholders of, and implementing action plans related to DX promotion.

The logistics industry in Japan continues to face pressure from factors including a labor shortage and aging drivers and seafarers, while demand for logistics—especially for small-lot cargo—is on the rise. In addition to the “2024 problem”2 in logistics, a future lack of logistics transportation and storage capacity has become one of the chemical industry’s most pressing issues. Moreover, chemical logistics involves a wide range of transportation methods and conditions due to the cargo’s unique properties, as well as packaging, weight, and other characteristics. This creates challenges in implementing effective measures on a per-company basis, and so we helped establish the working group to promote industry-wide initiatives.

1. Established in October 2021 by the Ministry of Economy, Trade and Industry (METI) and the Ministry of Land, Infrastructure, Transport and Tourism (MLIT), it aims to develop a roadmap for realizing a Physical Internet in Japan. The “Physical Internet” concept applies the idea of Internet communication—in which a chunk of data is defined as a packet and is exchanged efficiently—to the physical world of logistics.

https://www.meti.go.jp/shingikai/mono_info_service/physical_internet/index.html

2. Refers to various issues faced by the logistics industry, including a labor shortage due to a clause in the Work Style Reform Act on maximum overtime for professional drivers that will take effect in April 2024.

Contributing to CO₂ absorption

Reforestation in the Joint Demonstration Project for Woody Biomass Production in Shunan City

On September 1, 2022, Yamaguchi Prefecture’s Shunan City, Tosoh, and three other companies agreed to conduct a joint reforestation demonstration as part of the Joint Demonstration Project for Woody Biomass Production. Based on this agreement, the parties planted fast-growing trees in Mukaidake, in Shunan City’s Heta District.

The project aims to promote using forestry resources and the local production and consumption of woody biomass to create a sustainable forestry management model, through reforestation using fast-growing trees. It arose from the Partnership Agreement on Woody Biomass Usage and Forestry Improvement, signed on December 15, 2021, initiated by the Shunan City Wood Biomass Use Promotion Council, which was formed in January of that year.

The five parties will continue to promote efforts to produce woody biomass using municipal forests.

Tree-planting ceremony

Joining the Blue Carbon promotion project

To encourage conservation of the Oshima tidal flat which is under its jurisdiction, Shunan City has begun to utilize blue carbon as an initiative to decarbonize the area, thus reducing a cause of global warming in CO₂.*

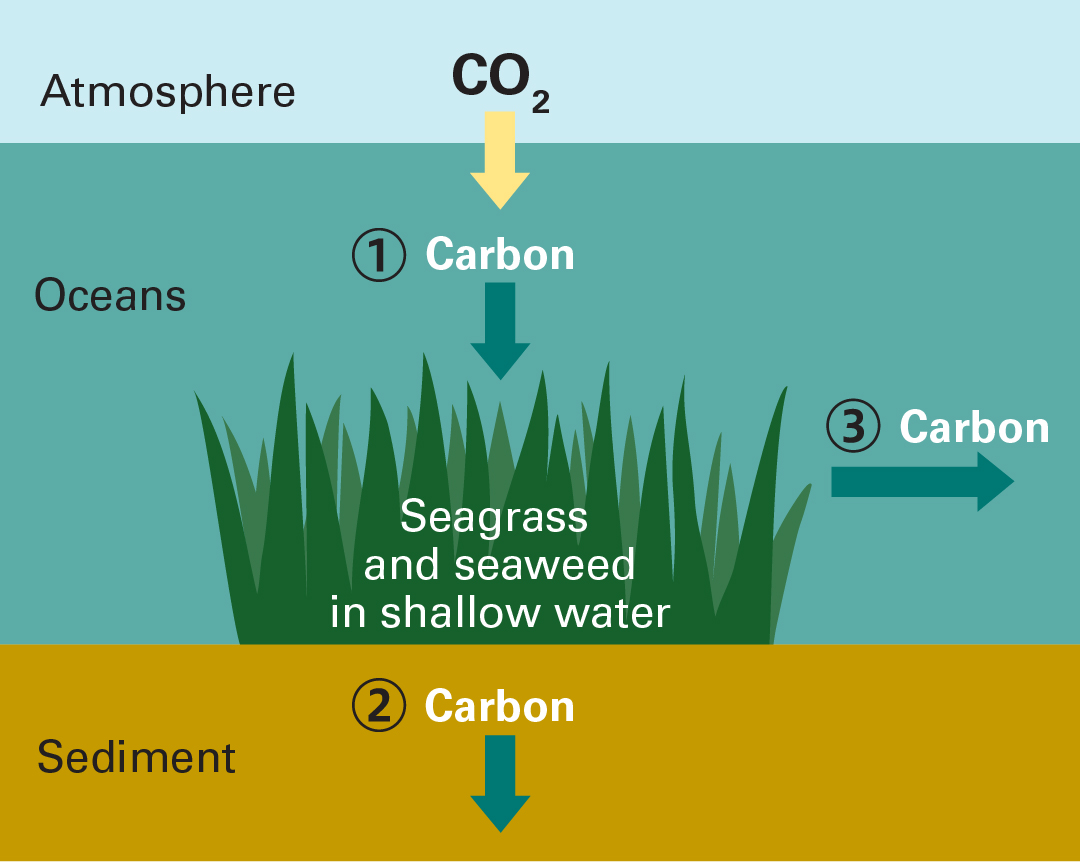

*Blue carbon refers to the carbon absorbed by seagrass and other marine organisms. Seagrass can absorb significant amounts of CO₂, taking CO₂ from the atmosphere that dissolves into the ocean. The more seagrass there is, the more substantial amounts of CO₂ it can absorb. In October 2009, the United Nations Environment Programme (UNEP) named the carbon captured in marine ecosystems “blue carbon” in its report.

The Oshima tidal flat absorbed 32.4 tons of CO₂ throughout fiscal 2023. Tosoh supports this project by purchasing and utilizing the recently created J Blue Credits.

Source: Created by Tosoh using Blue Carbon data provided by Japan's Ministry of Land, Infrastructure, Transport and Tourism (MLIT)

Isolation and storage mechanisms in blue carbon ecosystems

- Atmospheric CO₂ is taken up by blue carbon ecosystems in shallow water areas through photosynthesis, isolation, and storing CO₂ as organic matter.

- As the organisms in these ecosystems die and accumulate on the seafloor, they continue to be buried in lower sediment layers, with the carbon accumulating as blue carbon.