Responsible Care (RC) activities

Based on the recognition that environmental protection and safety and health are fundamental and important issues in business operations, the Tosoh Group has established the Basic Principles Regarding the Environment, Safety, and Health and Action Guidelines, taking into consideration the Japan Chemical Industry Association's Basic Policy on the Environment, Health and Safety. It has also established a Responsible Care (RC) promotion system to promote RC activities.

Environment, safety, and health basic principles

Based on the recognition of the prime importance of environmental protection and the assurance of safety and health, the Tosoh Group is engaged in continuous RC activities throughout a product’s life cycle, from R&D, manufacture, use or consumption, through recycling or disposal. We will contribute to the sustainable development of society through continuous voluntary RC activities and constant innovation in chemistry.

Action guidelines

Action guidelines

Employees and officers of the Tosoh Group have established the following action guidelines to serve as the basis for putting into practice the company’s environment, safety, and health principles.

1. Environmental Protection

・Aim to maximize the effective use of resources through energy conservation, resource conservation, and the 3Rs—reduce, reuse, and recycle—and to minimize the environmental impact of our business activities and help create a recycling-oriented society.

・Promote community-based environmental protection activities on the recognition that the conservation of biodiversity leads to the sustainable development of society.

2. Ensuring Safety

・Always recognize that safety takes precedence over everything else.

・Strive to comprehensively and quantitatively identify and reduce risks in order to eliminate accidents and disasters and ensure stable operations.

・Strengthen the emergency response system, including for natural disasters.

3. Chemical Product Safety

・Strive to obtain accurate information on all chemical substances handled in research, development, and production, including new products, and ensure appropriate management.

・Place the highest priority on environmental protection and ensuring safety and health in the provision of products and services.

・Strive to heighten customer satisfaction through quality control and safety in logistics.

4. Promoting Communication

・Proactively promote communication with stakeholders through information sharing and dialogue.

What is Responsible Care?

Responsible Care is a voluntary initiative undertaken to ensure the environment, safety, and health of companies that handle chemical substances in all processes from development, manufacturing, distribution, use, final consumption and recycling to disposal, as well as to publicize the results and engage in social dialogue.

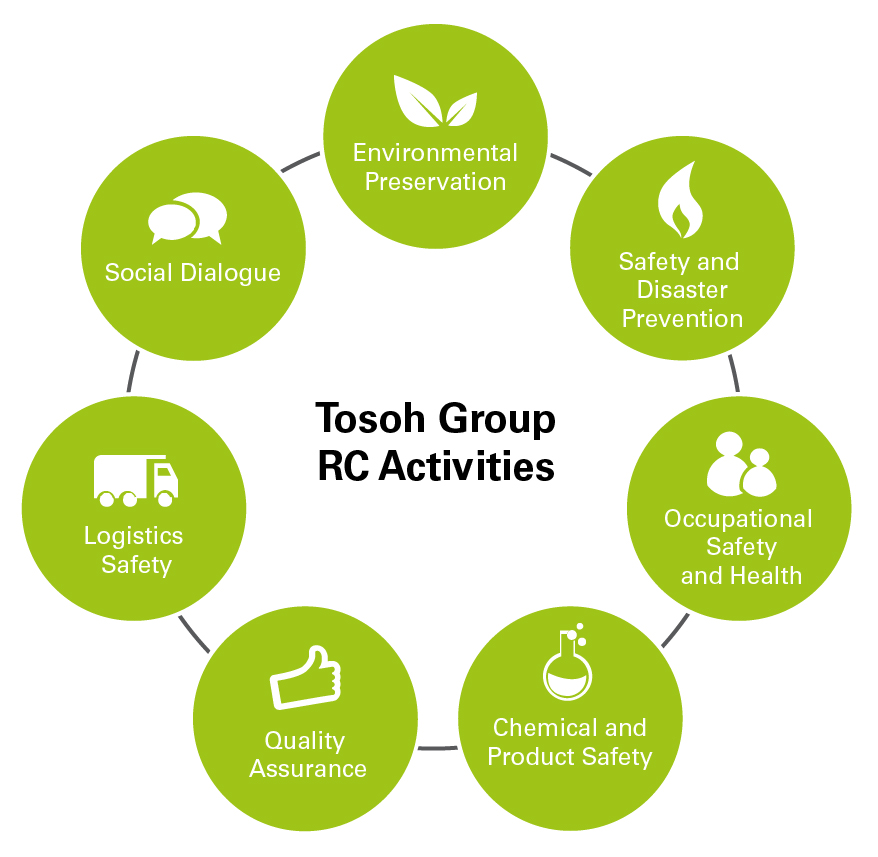

Tosoh Group RC activities are not limited to compliance with laws and regulations, but also cover environmental protection, safety and disaster prevention, occupational safety and health, chemical and product safety, quality assurance, logistics safety, and voluntary dialogue to earn the trust of society.

The International Council of Chemical Associations published the Responsible Care Global Charter in 2006 (revised in 2014). Tosoh signed the Global Charter in February 2006 and the revised version in September 2014.

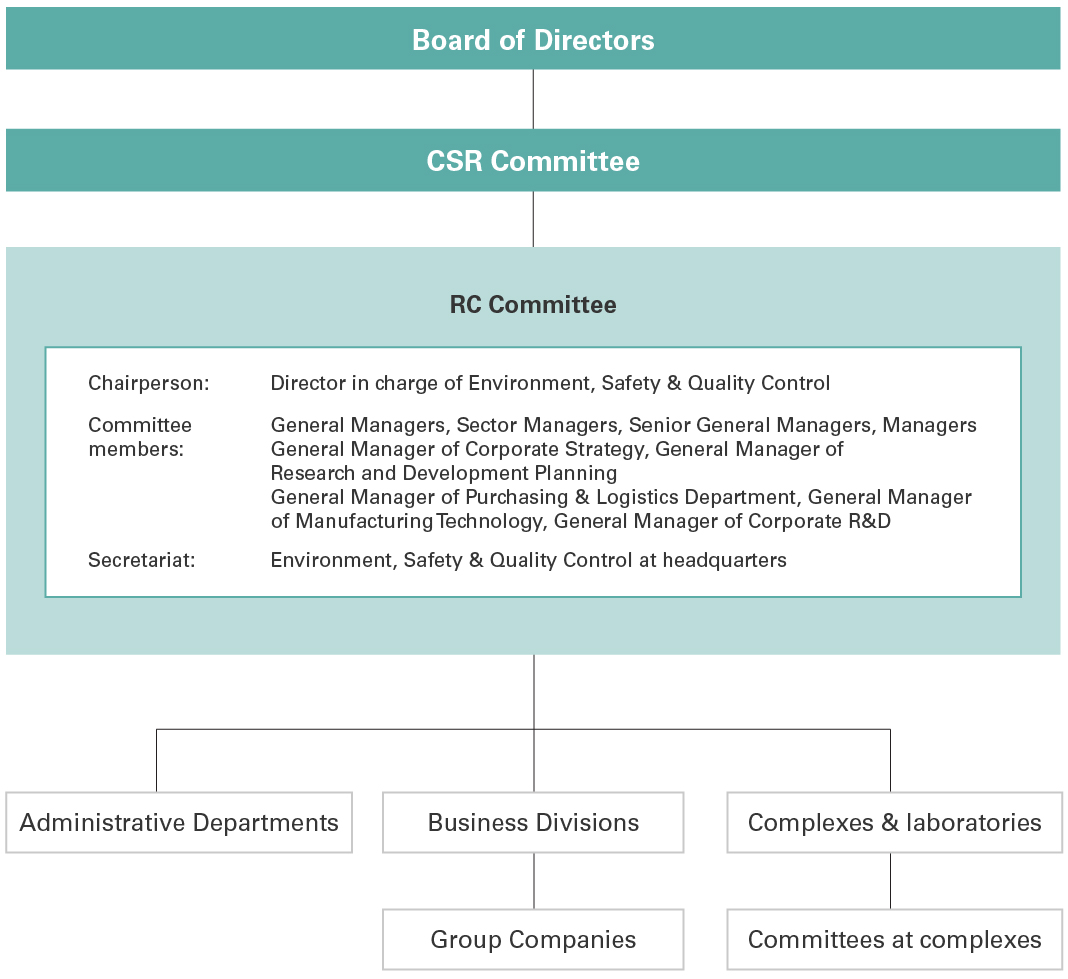

RC promotional structure

We are working on the following system to promote RC activities.

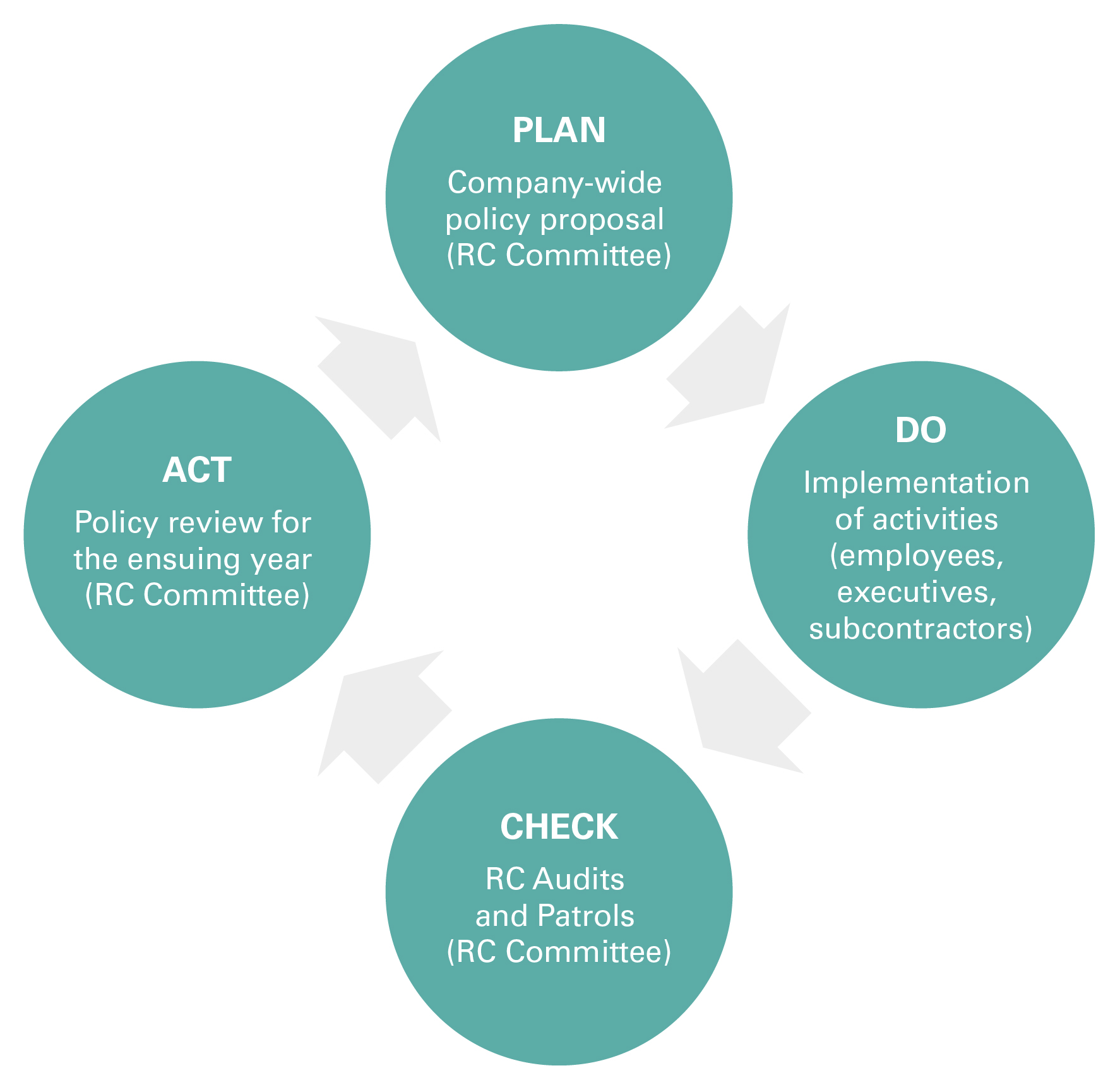

RC activity cycle

| | Tosoh | Tosoh Group |

| P | Establish company-wide policies | Establish policies for each company |

| D | Promote activities in line with policies |

| C | Conduct an audit of activities(RC audit) | Confirm activities through environmental and safety patrols |

| A | Review company-wide policies based on audit results and the activities of each group company | Review each company's policies |

List of activity targets and achievements

RC activity targets and achievements

★★★ Achieved

★★ In progress

★ Not achieved

RC slogan

Fiscal 2023:

The “new normal” as an opportunity to step up! Tosoh Group RC activities with new structure, ingenuity, and determination.

Fiscal 2024:

Tosoh Group RC activities: technology and activities for the next generation, achieved through the enthusiasm of each and every one of us.

Safety and disaster prevention / Occupational safety and health

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Zero Accidents and Injuries Resulting in Lost Time | Not achieved: Three accidents and seven injuries resulting in lost time (three employees and four subcontractors) | ★★ | Policy: Zero Accidents and Injuries Resulting in Lost Time |

| | (1) Ensure basic safety behavior - Establish practice-based hazard prediction training

- Continue 5S activities

| (1) Continue 5S and KY as part of daily operations | (1) Ensure basic safety behavior - Continue practical hazard prediction, promotion of safety awareness education

- Continue 5S activities

|

(2) Improve comprehensiveness of risk assessment - Priority: Continue reverification of multiple layers of protection

| (2) Conducting risk assessment based on multiple layers of defense and using fault tree analysis (FTA)Company-wide deployment of abnormal reaction information system | (2) Advance risk assessment - Priority: Continue to re-verify multiple layers of protection

- Priority: Train Process Safety Engineers (PSEs)

|

(3) Undertake efforts to eliminate similar accidents and occupational injuries - Priority: Reinforce safety management for outsourced operations

- Laterally deploy accident and occupational injury case studies, consider reflecting in standards

| (3) Undertaking improvement activities based on lessons learned from accidents and industrial accidentsWorking to improve issues identified in outsourced operation systemConducting accident explanatory briefings, deploying laterally, and reflecting the results in standards | (3) Undertake efforts to eliminate similar accidents and occupational injuries - Priority: Reinforce safety management for outsourced operations

- Laterally deploy accident and occupational injury case studies, consider reflecting in standards

|

| (4) Maintain and improve construction systemPriority: Organize and improve issues related to risk assessment system operationConsider initiatives for skill improvement, including learning methods to instruct workers to pay attention to unsafe behavior on-site | (4) Verified presence of systemic defects based on past work-related accidentsOngoing operation of spiral-up framework to improve system | (4) Maintain, improve construction system - Organize and improve issues related to risk assessment system operation

- Consider skill improvement initiatives, including learning methods to instruct workers to pay attention to unsafe behavior on-site

|

| 2) Policy: Promotion of Earthquake and Tsunami Countermeasures | ★★★ | Policy: Promotion of Earthquake and Tsunami Countermeasures |

| | Ensure earthquake resistance of important buildings and promote tsunami countermeasures | Conducting seismic reinforcement, flood control work as planned | Ensure earthquake resistance of important buildings and promote tsunami countermeasures |

| 3) Policy: Maintenance and Improvement of Independent Safety Measures | ★★★ | Policy: Maintenance and Improvement of Independent Safety Measures |

| | Renew high-pressure gas certification at Nanyo Complex | High-pressure gas certification renewal proceeding on schedule | (1) Actions to be taken under new certification system - Proactively consider introduction of smart security technology

- Fortify cyber security countermeasures

(2) Conduct security management status survey at Yokkaichi |

Actions to be taken under new certification system - Proactively consider introducing smart security technology

- Develop cyber security system

| Proactively considering introductionDeveloping cyber security system (established committee) |

| 4) Policy: Zero Accidents and Injuries Resulting in Lost Time at Group Companies | Not achieved: Two accidents and 13 injuries resulting in lost time (10 employees and three subcontractors) | ★★ | Policy: Zero Accidents and Injuries Resulting in Lost Time at Group Companies |

| | (1) Provide guidance to group companies - Priority: Continue environment and safety exchange meetings

- Priority: Promote utilization of Ankan-Net meetings

| (1) Provided guidance to group companies - Environment and safety exchange meetings: Nine

- Safety guidance by outside safety experts: 44 times at 14 companies

- Ankan-Net meetings: Two

- Education by outside instructors and others: Four times for safety, twice for environment

| (1) Provide guidance to group companies - Priority: Continue environment and safety exchange meetings, etc.

- Priority: Promote utilization of Ankan-Net meetings (two)

Education sessions (four safety, two environmental)

|

| (2) Continue promotion of earthquake and tsunami countermeasures at Group companies | (2) Conducting survey of each company's response status regarding important buildings | (2) Promote earthquake and tsunami countermeasures at Group companies - Promote earthquake resistance of important buildings

|

| (3) Cooperate in business auditing for overseas Group companies (manufacturing companies) | (3) Attended operations audits at two companies(Tosoh Hellas single Member S.A., Tosoh Advanced Materials Sdn.Bhd.) | (3) Cooperate in business auditing for overseas group companies (manufacturing companies) |

Environmenal protection

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Compliance with Laws and Regulations (zero deviations from regulatory or agreed values) | Deviations from regulatory values: Two (one atmospheric, one noise) | ★★ | Policy: Compliance with Laws and Regulations (zero deviations from regulatory or agreed values) |

| | (1) Ensure compliance with agreed values - Strengthen monitoring of facilities specified by laws and regulations; promote preventive measures related to deviations

- Conduct re-education of cases of deviation from agreed values (including dissemination of information, etc.)

| (1) Seven cases of deviation from agreed values - Enhanced facility monitoring, conducting of meetings to report issues

| (1) Ensure compliance with agreed values - Strengthen monitoring of facilities specified by laws and regulations; promote preventive measures related to deviations

- Review of non-routine work standards that may cause deviations

- Conduct re-education of cases of deviation from agreed values (including dissemination of information, etc.)

|

(2) Ensure compliance with laws and regulations - Ensure compliance with laws and regulations other than measurement items

- Promote environmental education; improve employee competence

| (2) Ensured compliance with laws and regulations

Conducted environmental education, explanation of legal revisions, education for pollution prevention managers, etc. | (2) Ensure compliance with laws and regulations - Ensure compliance with laws and regulations other than measurement items

- Promote environmental education; improve employee competence and awareness

|

| 2) Policy: Compliance with Laws and Regulations at Group Companies | | Policy: Compliance with Laws and Regulations at Group Companies |

| | - Priority: Improve legal compliance management level

- Reinforce guidance through use of environmental consultants

- Conduct periodic checks, guidance on compliance with environmental laws and regulations

| - Provided guidance in three instances on waste management operations, interpretation of laws

- Regular distribution and dissemination of information on revisions to environmental laws and regulations

| - Priority: Improve legal compliance management level

- Reinforce guidance through use of environmental consultants

- Conduct periodic checks, guidance on compliance with environmental laws and regulations

|

| 3) Policy: Reduce PRTR Emissions by 30% Compared with FY2016 (424 metric tons) | PRTR emissions: 399 metric tons | ★★★ | Policy: Reduce PRTR Emissions by 30% Compared with FY2016 (424 metric tons) |

| | - Implement n-hexane reduction plan

- Continue to study monochlorobenzene (MCB) emission control (wastewater)

- Select candidate substances for reduction, study reduction measures in accordance with revised law

| - n-hexane reduction measures progressing as planned

- Continuing to study MCB emission control

| - Implement n-hexane reduction plan

- Continue to study MCB emission control (wastewater)

- Study, promote maintenance and reduction of emissions upon facility expansion

|

| 4) Policy: Effective Use of Industrial Waste | Landfill industrial waste volume: 874 metric tons | ★★★ | Policy: Effective Use of Industrial Waste |

| | - Undertake measures to reduce emissions by 75% in FY2026 compared with FY2001 levels, establish mechanism (equivalent to 1,262 metric tons)

- Reduce total industrial waste discharge, external disposal

- Maintain recycling rate of 90% or better

| - Continue considering final landfill volume reduction initiatives

- Promote total emission reduction, external disposal

- Continue promotion of recycling

| - Continue toward 75% reduction in FY2026 compared with FY2001 results

- Reduce total industrial waste discharge, external disposal

- Maintain recycling rate of 0% or more

|

| 5) Policy: Promotion of Planned Disposal of Polychlorinated Biphenyl (PCB)-Containing Equipment | ★★★ | Policy: Promotion of Planned Disposal of Polychlorinated Biphenyl (PCB)-Containing Equipment |

| | - Implement planned disposal of equipment containing low PCB concentrations in coating

| - Promote disposal based on plan

- Conformed paint film containing low PCB conentrations (tanks: one at Nanyo Complex, two at Group companies)

- Conducted survey on disposal status

| - Implement planned disposal of target equipment containing low PCB concentrations

|

| 6) Policy: Promotion of Biodiversity Preservation Activities | ★★★ | Policy: Promotion of Biodiversity Preservation Activities |

| | (1) Promote biodiversity preservation activities - Promote forest, river, ocean preservation activities, etc.

- Promote community contribution activities such as city street cleanups

- Promote waste 3R activities, etc.

| (1) Conducted cleanup activities in each region | Promote biodiversity conservation activities as part of promotion of cooperation with communities activities (dialogue with society) |

| (2) Consider activities that take into account regional characteristics | (2) Effective use of wood from pruned trees, other materials for biomass fuel in Shunan City |

Quality management

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Reduce Serious Product Complaints to Zero | ★★ | Policy: ReduceSerious Product Complaints to Zero |

| | Priority: Reduce product complaints through strengthening of cooperation among quality assurance, manufacturing, and business divisions - Cooperate among quality assurance, manufacturing, and business divisions in understanding customer applications, deliver products

- Review specifications, other descriptions and measure to prevent endogenous foreign matter

- Prevent recurrence of complaints with same cause

- Confirm status of complaint prevention efforts, maintenance of prevention measures through on-site inspection, risk assessment, etc.

| Number of serious product complaints: One - Incidents of customer equipment damage: One

- Reviewing contents of delivery specifications

- Reviewing contents of delivery specifications in Tosoh's format

- Review of internal delivery specifications

- Review of measures to prevent endogenous foreign matter

| - Priority: Reduce product complaints by strengthening cooperation between quality assurance, manufacturing, and business divisions

- Confirm contents of delivery specifications

- Review of delivery specifications in Tosoh's format

- Maintenance of internal delivery specifications

- Review of measures to prevent endogenous foreign matter

- Prevent recurrence of similar complaints

- Prevent complaints through on-site inspection, risk assessment; confirm maintenance status of preventive measures

- Activity policy for preventing customer equipment damage during loading, unloading described in Reducing the Rate of Logistics Complaints and Issues

|

| 2) Policy: Strengthening Supply Chain Management | ★★★ | Policy: Strengthening Supply Chain Management |

| | (1) Strengthen quality control system of outsourced manufacturing sites - Conduct quality audits of outsourced manufacturing sites

| (1) Strengthened quality control system of outsourced manufacturing sites - Conducted quality audits of 33 contract manufacturing companies

| (1) Strengthen quality control system of outsourced manufacturing sites - Conduct quality audits of outsourced manufacturing sites

- Consider measures to handle purchased and resold products, exchanged products

|

(2) Strengthen management of raw material (including packaging materials) suppliers - Priority: Systematically implement raw material supplier audits

| (2) Strengthened management of raw material (including packaging materials) suppliers - Conducted on-site and document audits at 50 companies

| (2) Strengthen management of raw material (including packaging materials) suppliers - Priority: Systematic implementation of raw material supplier audits

|

| 3) Policy: Confirmation of Quality Control System | ★★ | Policy: Confirmation of Quality Control System |

| | (1) Continue internal, Group company quality control surveys - Conduct survey of Group company quality control systems

| (1) Conducted internal, Group company quality control surveys - Detected zero incidents with serious environmental or safety impact

| (1) Continue internal, Group company quality control surveys - Conduct survey of Group companies' quality control systems

|

(2) Conduct quality control survey follow-up for Group companies - Provide education on quality compliance

| (2) Conducted quality control survey follow-up for Group companies - Laterally deployed other companies' quality control case studies

| (2) Conduct quality control survey follow-up for group companies - Continue quality compliance education

|

Pharmaceutical Affairs Act

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Reinforcement of Quality Assurance System for Bioscience Division Products | ★★★ | Policy: Reinforcement of Quality Assurance System for Bioscience Division Products |

| | (1) Establish legal compliance system in response to revised Pharmaceutical Affairs Agency Law | (1) Mandatory placement of bar code labeling on packaging for in vitro diagnostic products and medical devices to ensure traceability - Complied with bar code labeling as noted above to ensure traceability

| (1) Establish legal compliance system in response to revised Pharmaceutical Affairs Agency Law |

| (2) Monitor quality assurance system of BS product manufacturing facilities | (2) Confirmed quality assurance system for diagnostic products - Conducted regulatory audit of one outsourced manufacturing facility and five BS sites

| (2) Monitor quality assurance system of BS product |

Chemical and product safety

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Zero Occurrence of Major Nonconformities in Compliance with Domestic and International Chemical Substance Laws and Regulations | Zero occurrence of major nonconformities | ★★★ | Policy: Zero Occurrence of Major Nonconformities in Compliance with Domestic and International Chemical Substance Laws and Regulations |

| | (1) Comply with legal obligations - Ensure risk assessment of chemical substances

- Maintenance and management of SDS/labeling

- Respond to, manage sales of substances newly designated under Poisonous and Deleterious Substances Control Law

| (1) Complied with legal obligations - Confirmed implementation of risk assessment of chemical substances at all sites

- Completed revised JIS compliance for SDS for products subject to Poisonous and Deleterious Substances Control Law revisions

- Confirm status of sales management of hazardous substances at branches, etc. and correct deficiences

| (1) Comply with legal obligations - Ensure risk assessment of chemical substances

- Maintain and manage SDS/labeling

- Response to/management of sales of newly added substances under Poisonous and Deleterious Substances Control Law

|

(2) Respond to notifications, applications - Ensure implementation of notification, application under Law Concerning the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc., Industrial Safety and Health Law

- Respond appropriately to overseas laws and regulations

| (2) Responded to notifications, applications - Identified, responded to notifications and applications at safety review meetings promptly

- Revised explanatory materials regarding audits and notifications for internal use

- Confirmed appropriateness of REACH registration for exports to EU

Provided support to business units for Turkey REACH registration | (2) Respond to notifications, applications - Ensure compliance with Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc., Industrial Safety and Health Law chemical substance application system

- Comply appropriately with overseas laws and regulations

|

Logistics safety

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Reduce Logistics Complaint and Problem Incidence Rate to 70 Parts Per Million (ppm) or Fewer | Logistics complaints and problems: 101 ppm | ★★ | Policy : Reduce Logistics Complaint and Problem Incidence Rate to 70 Parts Per Million (ppm) or Fewer |

| | Comprehensive implementation of the following four items to achieve policy: - Ensure company is contacted promptly in the event of issues

- Ensure once-daily cargo movement confirmation against inventory

- Comprehensive management of work tools in place

- Perform comprehensive safety check when moving within customer premises

- Continue follow-ups and validation

- Continue issue prevention activities and confirmation of effectiveness through use of issue reporting system

| Disseminated four items, introduced effective case studies regarding item c. - Completed management of work tools in place due to improved thoroughness, decrease in number of cases

- Saw increase in issues resulting from vehicle equipment malfunctions

- Saw frequent occurrence of customer equipment damage, primarily during backward movement

● Began construction of model workplace

● Sequentially implemented follow up on measures to prevent recurrence of issues, considering additional measures

● Implemented trend analysis and alerts based on past issues | Comprehensive implementation of the following four items to achieve policy: - Ensure company is contacted promptly in the event of issues

- Ensure once-daily cargo movement confirmation against inventory

- Comprehensive management of work tools in place

- Perform comprehensive safety check when moving within customer premises

- Review, consider efforts to ensure awareness of four items

- Consider constructing model workplace

- Reinforce measures to prevent customer equipment damage during loading, unloading

- Continue follow-up, effectiveness checks

- Continue issue prevention activities using issue reporting system, confirm effectiveness

|

| 2) Policy: Zero Serious Incidents | Serious incidents: 0 | ★★★ | Policy: Zero Serious Incidents |

| | - Continue conducting bridge resource management (BRM) training, navigational/operational diagnostics for time chartered vessels

- Raise safety awareness through BRM training for time chartered vessels and ongoing voyage and operation diagnoses

- Provide ongoing support for Tosoh Logistics Corporation's efforts to rebuild culture of safety

| - Conducted voyage, transportation diagnostics for 13 vessels

- Conducted KYT briefing sessions, KY workplace patrols, reacquainted employees with work rules

| - Continue BRM training, voyage/operational diagnostics for time chartered vessels

- Raise safety awareness through BRM training for time chartered vessels and ongoing voyage and operation diagnoses

- Provide ongoing support for Tosoh Logistics Corporation's efforts to rebuild culture of safety

|

| 3) Policy: Ensure Preventive Logistics Safety | | ★★ | Policy: Ensure Preventive Logistics Safety |

| | - Priority: Implement measures to improve high-risk customer cargo handling

- Priority: Implement safety measures for bromine ISO tank container transport

- Priority: Conduct risk assessment of on-site operations, consider measures to reduce risk

| - Improved hazardous locations at lorry suppliers, responded to requests for heat countermeasures

- Launched improvement measures at hazardous locations at new vessel delivery site

- No nonconformities found at bromine receiving facilities

- Considered introducing chemical substance risk assessment for logistics processes

- Conducted risk assessment of on-site operations

| - Priority: Implement measures to improve high-risk customer cargo handling

- Priority: Implement safety measures for bromine ISO tank container transport

- Priority: Conduct risk assessment of on-site operations, consider measures to reduce risk

|

Social dialogue

| FY 2023 | FY 2024 Goals |

| Policy and plan | Results | Appraisal |

| 1) Policy: Promotion of Risk Communication | | ★★★ | Policy: Promotion of Risk Communication |

| | - Continue to conduct media training

| - Conducted media training at Yokkaichi Complex

| - Continue to conduct media training

|

| 2) Policy: Promotion of Cooperation with Local Communities | | ★★★ | Policy: Promotion of Cooperation with Local Communities |

| | - Conduct community dialogues, factory tours, neighborhood association social gatherings

- Promote interaction with local schools, cooperation with government

| | - Conduct community dialogues, factory tours, neighborhood association social gatherings

- Promote interaction with local schools, cooperation with government

- Promote biodiversity preservation activities

|